Work Table Options

Work table grid options for different needs

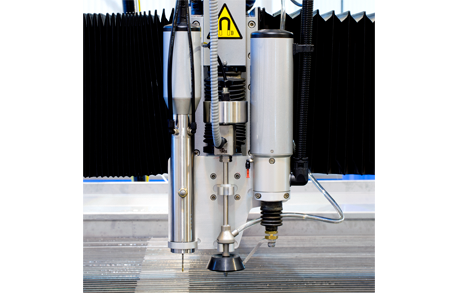

The work table grids are placed on/in the stainless-steel cutting tank. For all Water Jet Sweden machine systems (except Micro) the cutting tank is a standalone item. The purpose of this is to keep cutting accuracy even after hours of cutting. A standalone tank avoids that the frame and cutting tools are affected by heat and vibrations generated in the cutting tank.

Standard Grid – A galvanized grid frames mounted on a cutting table bolted into the machine tank. Each grid module is carefully processed be leveled for all new machines.

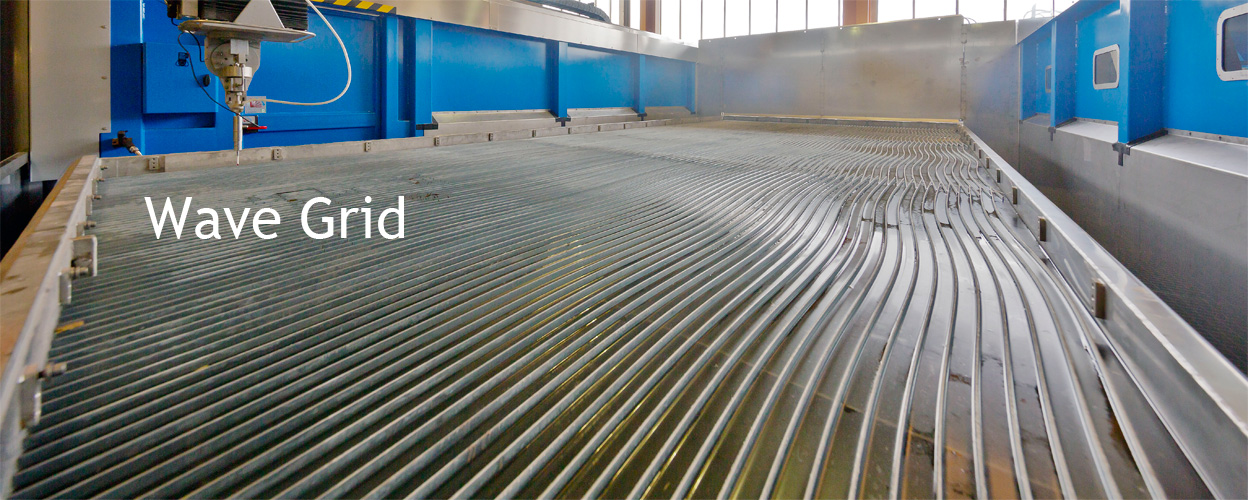

Wave Grid – This option is ideal when parallel cutting is required and causes less back splash underneath the material.

Tube Grid – A grid-system is ideally suited for cutting thick and heavy materials at low speed. The tubes are individually mounted on tube holders assembled on a galvanized grid, which is installed below water level.

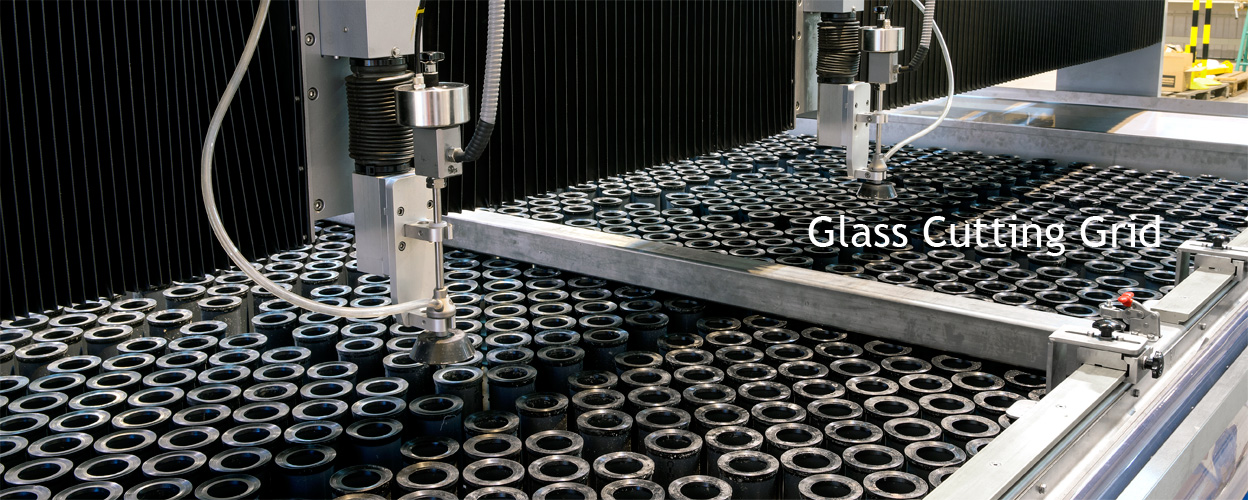

Glass Cutting Grid – A tube grid system specially developed for glass cutting. Plastic tubes with a top rubber seal make the table perfect for supporting brittle materials.

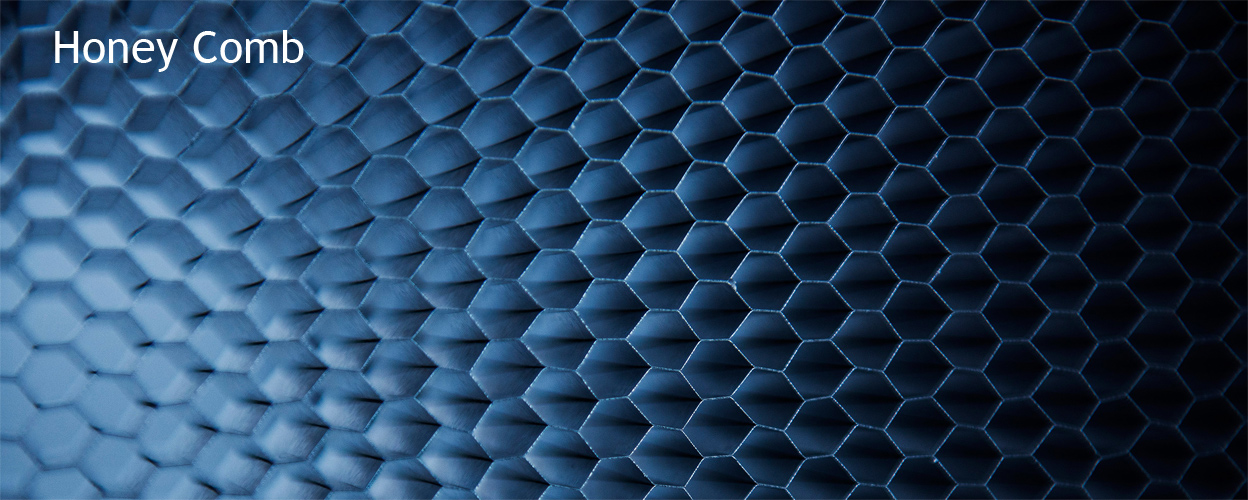

Honey Comb – This special grid is used for pure waterjet cutting (PWJ). It is made of thin, 50 mm wide aluminum stripes building a thick honeycomb shaped grid. The Honey Comb is placed on top of the existing table grids.

Contact

Five year performance warranty

We guarantee that all our machines keep the same tolerance level after five years as when the machine was first delivered.

Lifetime support by waterjet specialists

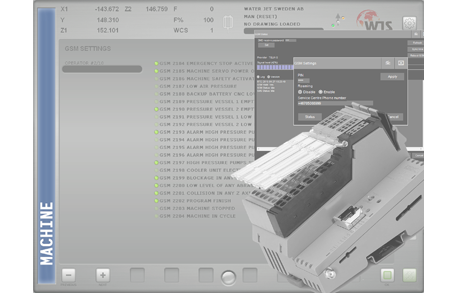

Our service team is highly specialized within the field of water jet cutting. Via our hotline support, our technical expertise is available on a 24/7 basis.

Klas Wallström

CMO

Sweden

Welcome

If you have questions, please call us at +46 457 455 440 or fill in the contact form and we will get in touch.