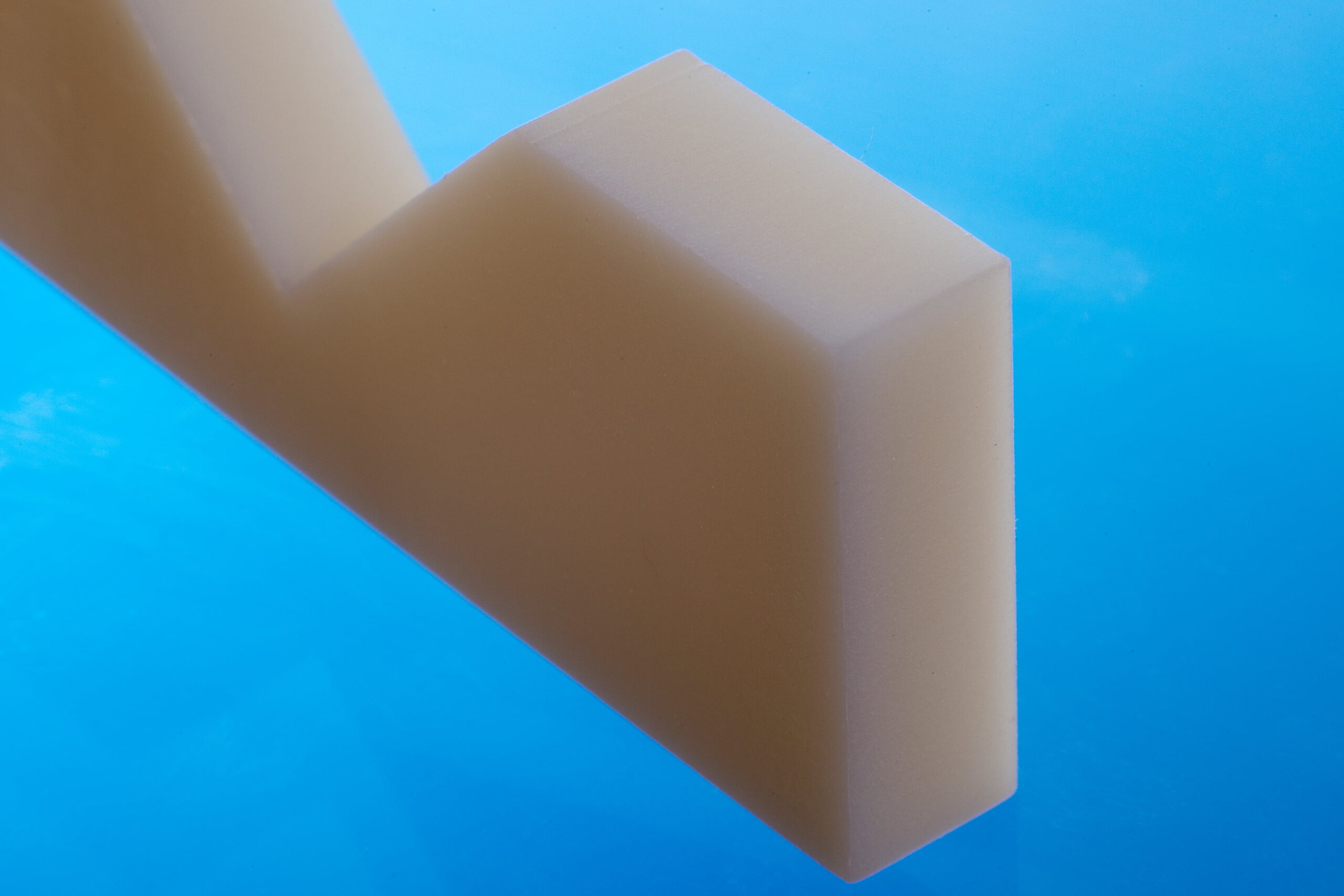

Plastic foam and insulation

Waterjet cutting is a highly efficient and precise method for working with plastic foam and insulation materials. By using a high-pressure water jet, this technique can cut through different densities and thicknesses of foam materials without the need for abrasives. This results in clean kerfs with minimal impact on the material, which is particularly beneficial for sensitive materials such as plastic foam and cellular rubber.

Pure waterjet cutting is proven beneficial compare to traditional methods

Benefits of using waterjet cutting for rubber, plastic and soft materials:

- High level of precision: Waterjet cutting allows precise and complex cuts, which is ideal for detailed shapes and patterns.

- No impact from heat: As the method does not generate heat, it prevents the risk of melting or deformation of the material, thus preserving its original properties.

- Flexibility: The method is suitable for both thin and thick materials, which makes it useful for a wide variety of applications in the insulation and packaging sector.

- Environmentally friendly process: Waterjet cutting does not produce any harmful emissions or dust, making for a cleaner working environment and reduced environmental impact.

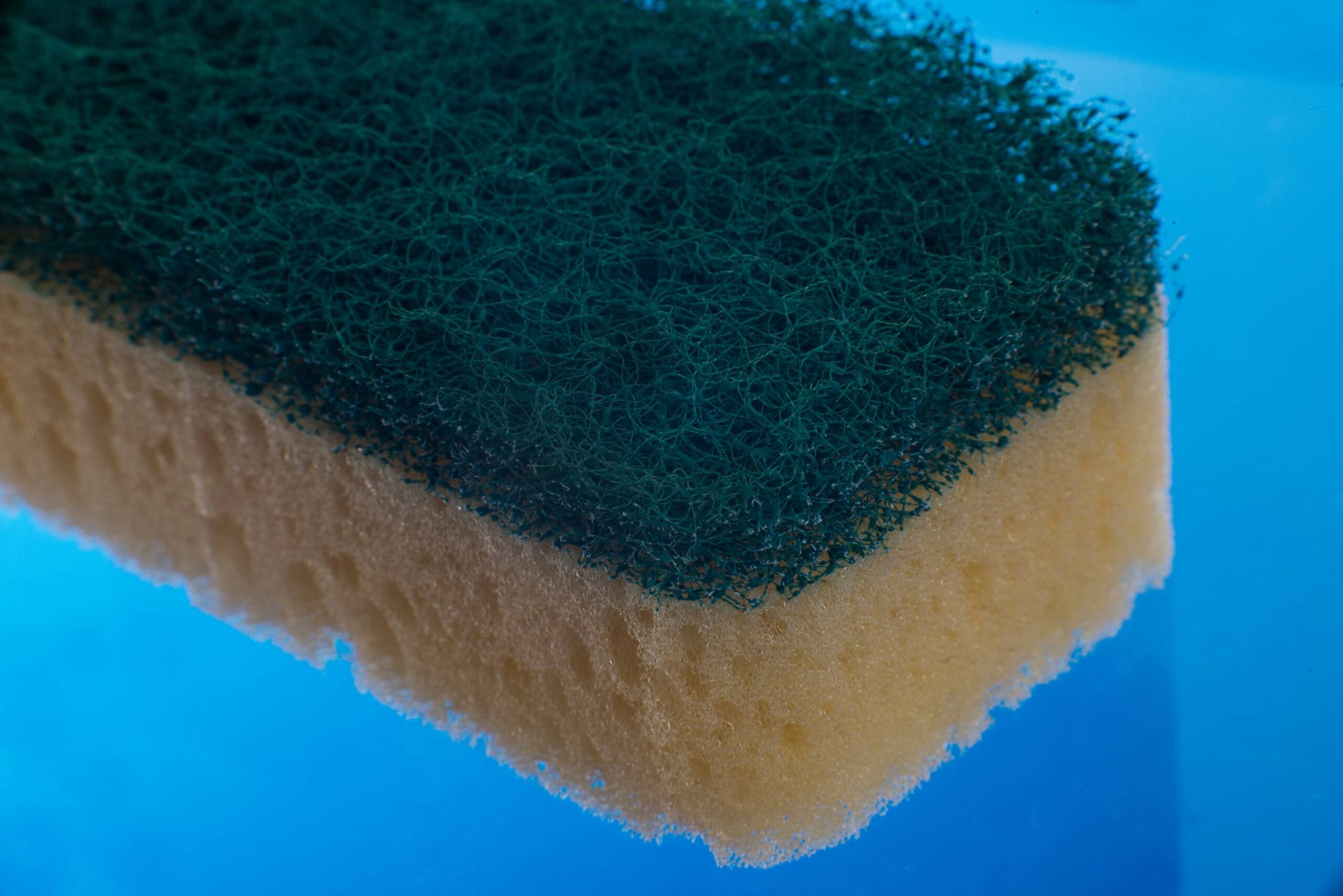

Areas of application:

- Insulation components: Manufacturing of insulation items for the construction and automotive industries.

- Packaging material: Production of customised packaging solutions that require precision and material integrity.

- Prototyping: Rapid and cost-effective production of prototypes before switching to mass production.

Choosing waterjet cutting for plastic foam and insulation materials ensures high quality, efficiency and durability of the final products.

Question: Is waterjet cutting a suitable method for cutting different types of plastic foam material?

Answer: Yes, waterjet cutting is well-suited to plastic foams – particularly delicate or porous materials. The cold cutting method produces clean, precise kerfs without heat, deformation or compression. However, water-absorbing foams can be more difficult to work with and require customisation.

Question: What are the benefits of waterjet cutting for plastic foam compared to other cutting methods?

Answer: Waterjet cutting provides precise kerfs without any impact from heat or mechanical stress. It works particularly well for thick sheets of foam, it is environmentally friendly and is suitable for complex shapes. The method requires no further finishing work and is cost-effective for both small and large volumes.

Question: Can waterjet cutting handle different densities and thicknesses of plastic foam?

Answer: Yes, water cutting can be customised to both density and thickness. For thicker and denser plastic foams adjustments in pressure and speed are required, while thinner materials can be processed faster and with less force – without compromising on precision.

Question: How does waterjet cutting affect the precision and quality of plastic foam components?

Answer: Waterjet cutting provides a high level of precision without affecting the cell structure. Kerfs end up smooth and even, which is important for both functionality and aesthetics. The method does not leave any burn marks or contamination, which makes it ideal for medical and hygienic applications.

Question: Which industries use waterjet cutting for plastic foam applications?

Answer: Industries that use waterjet cutting for plastic foam include furniture, automotive, construction, packaging, medical and sports industries. It is used for everything from insulation and sound-proofing to orthopaedic products and shock-absorbing packaging.