Composite materials

Waterjet cutting is an effective method for cutting a range of composite materials, such as carbon fibre-reinforced plastics, fibreglass and Kevlar. The high-speed jet of water used in abrasive waterjet cutting can cut through almost any material, making the technique particularly useful for complex and detailed shapes. It has a low contact force which eliminates the need for bulky tools and minimises the risk of delamination or damage to the material.

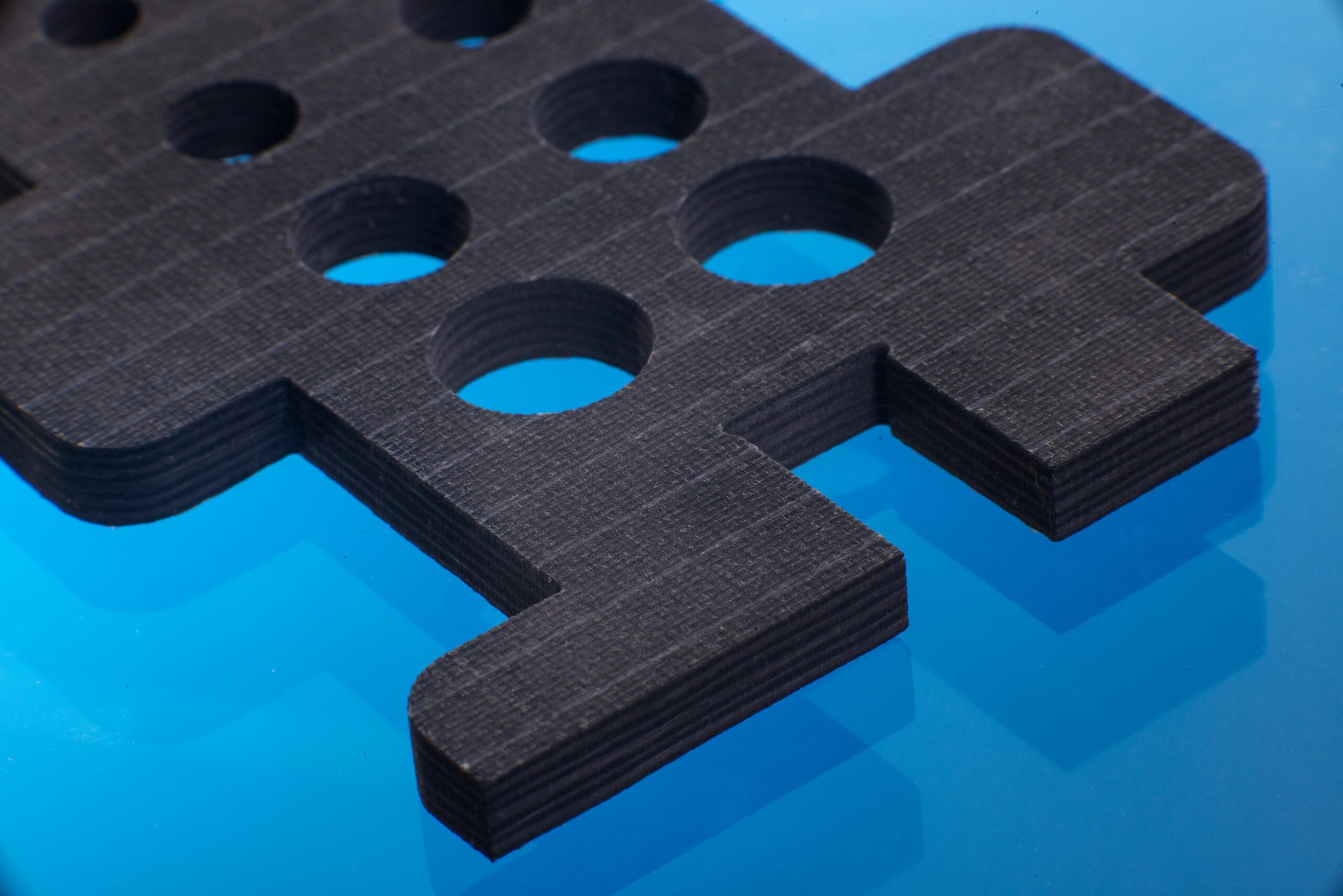

Carbon fiber or glass fiber reinforced materials CRP, CFRP, GRP, GFRP and C/C

One of the main advantages of waterjet cutting is that it is a cold method. This means that the material is not exposed to heat, which can change its properties or cause melting and deformation. This is particularly important when processing composites, where heat can lead to undesirable changes in the structure of the material.

Waterjet cutting is also versatile and can be used for composites made up of different materials, such as metal and rubber, in one single process. The fine, concentrated water jet cuts reliably and precisely in all directions with meticulous accuracy. This is what makes the technique ideal for applications where precision and quality are crucial.

In summary, using waterjet cutting for composite materials offers a range of benefits:

- No impact from heat: The material retains its original properties without the risk of heat-related damage.

- High level of precision: It is capable of creating complex and detailed shapes with a minimal risk of delamination.

- Versatility: It can process a variety of composite materials and combinations of materials in a single process.

These characteristics make waterjet cutting the preferred choice for many industries that work with composite materials.

Question: What are the benefits of using waterjet cutting for composite materials?

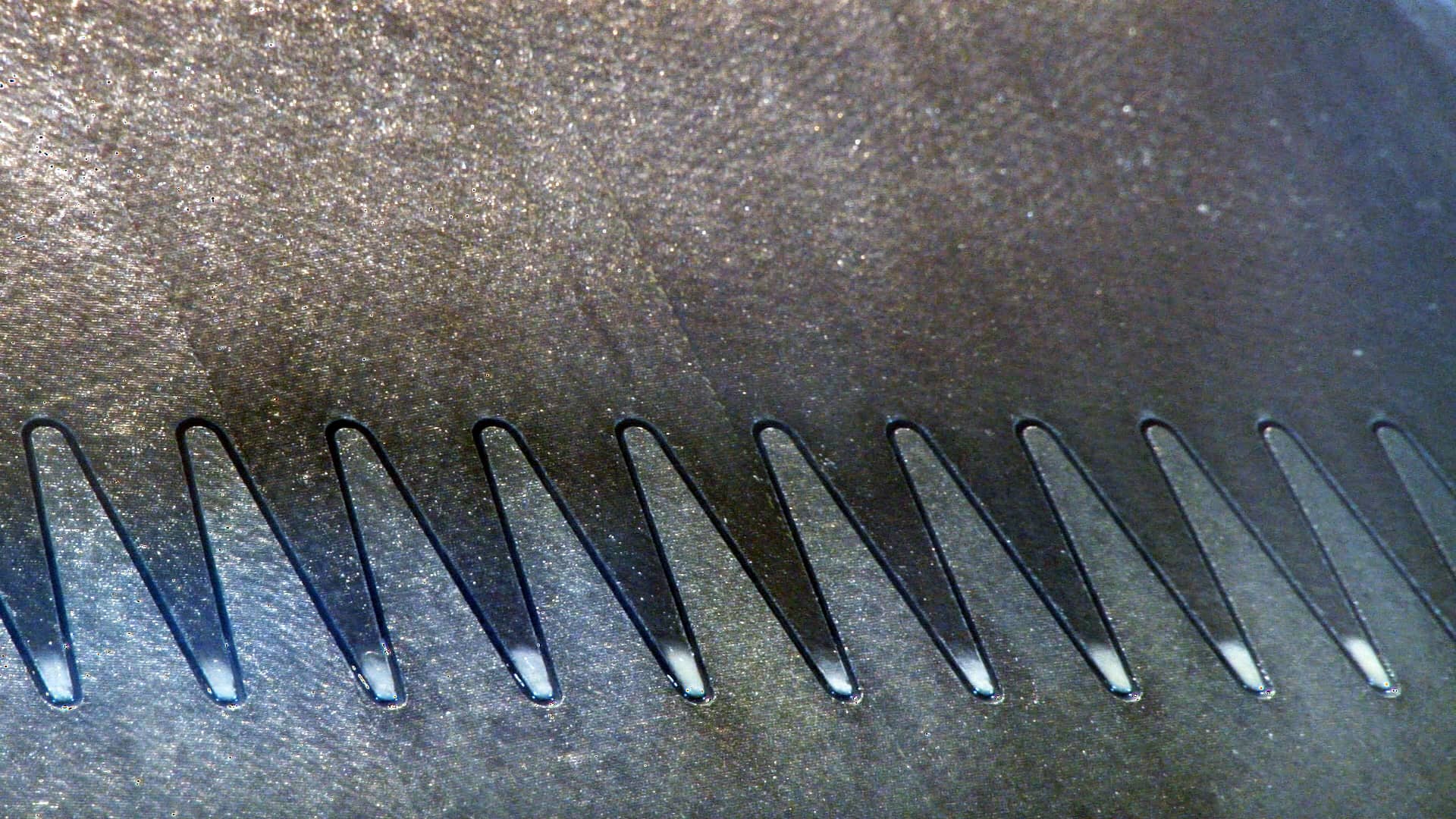

Answer: Waterjet cutting produces clean, precise kerfs in composite materials without the risk of delamination, fibre pull-out or thermal damage. The method requires minimal work with fixtures, has low tooling costs and does not generate any dust or gas emissions. It is suitable for both thin details and complex shapes, with a high level of quality and little material loss.

Question: Can waterjet cutting handle different types of composites, such as carbon fibre and fibreglass?

Answer: Yes, waterjet cutting can be used for a wide range of composites such as carbon fibre, fibreglass, Kevlar and metal/rubber combinations. The abrasive jet of water cuts materials without causing heat, dust or cracks – making it ideal even for advanced composite materials such as CFRP, GFRP and C/C.

Question: How does waterjet cutting affect the structural integrity of composite materials?

Answer: As waterjet cutting is a cold method it does not affect the structure of the composite. So, it does not create melting at the edges or micro-cracks. The result is a smooth, sharp edge with no fraying or delamination – even with thin or multi-layered materials.

Question: Is waterjet cutting suitable for complex shapes in composite materials?

Answer: Absolutely. The narrow, precise jet of water allows for intricate shapes and tight radii without the need for extensive clamping. Since waterjet cutting can produce a high level of detail, it is ideal for complex geometries in advanced composite manufacturing.

Question: Which industries use waterjet cutting for composite materials?

Answer: The aerospace industry, automotive and motorsports, maritime and construction industries use waterjet cutting for lightweight, strong composite components. The method is suitable for everything from trim parts to structural elements in high-performance materials.