Rubber, plastics and soft materials

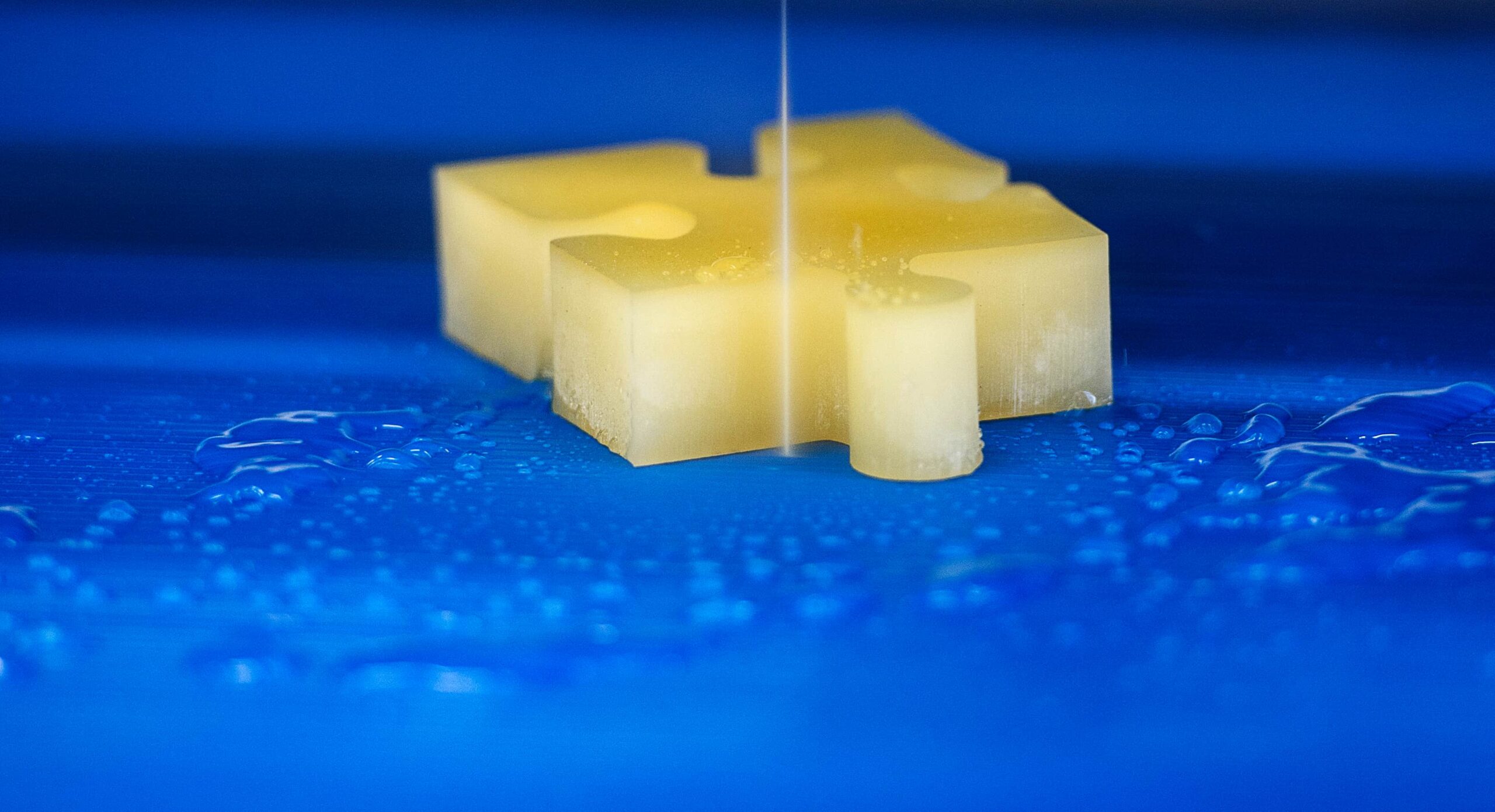

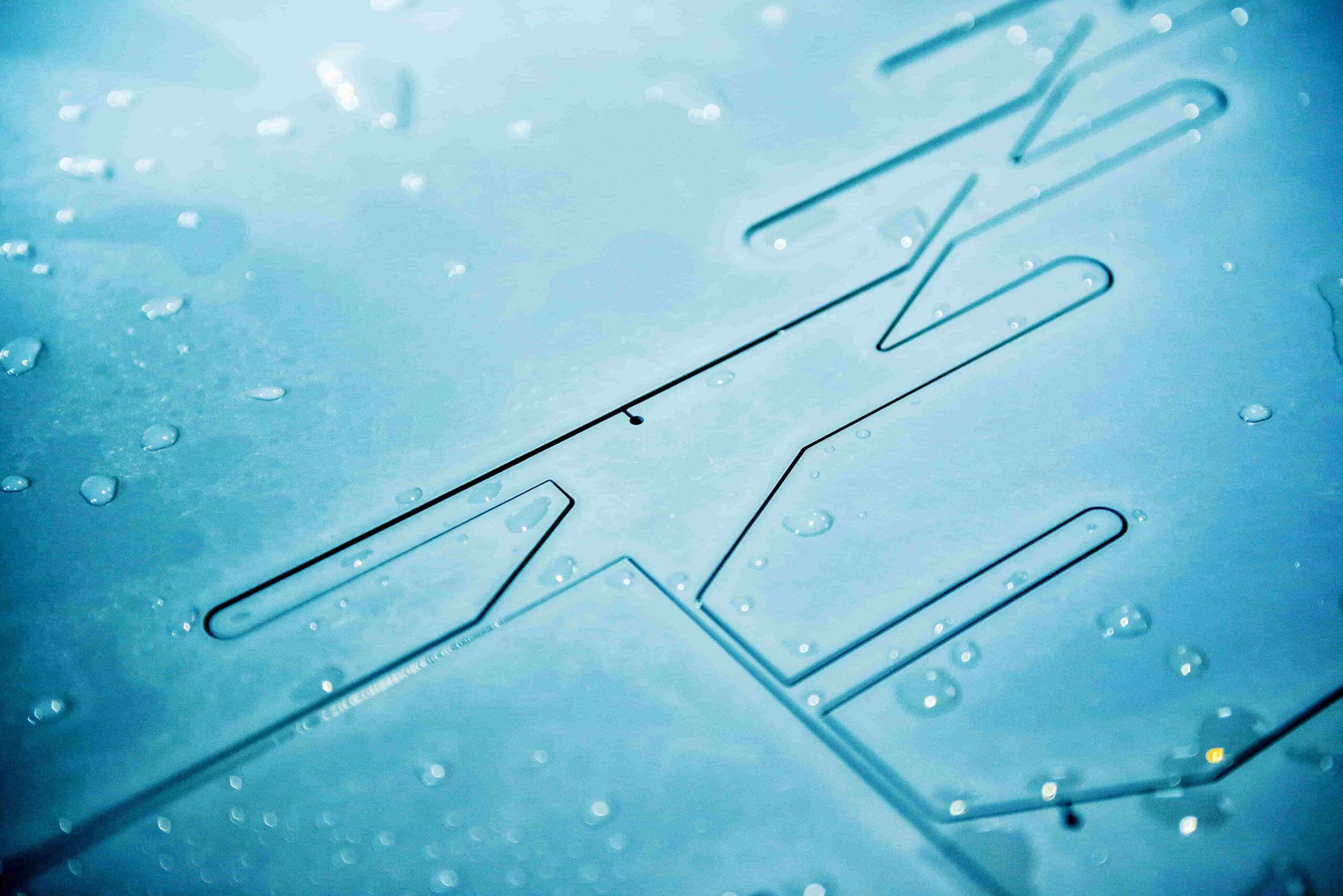

Waterjet cutting is an advanced and precise method that uses a high-pressure jet of water to cut through different materials. For soft materials such as rubber, plastics and foam, pure water jet (PWJ) cutting is particularly beneficial as it eliminates the need for abrasives and allows precise kerfs with minimal impact on the properties of the material.

Pure waterjet cutting is proven beneficial compare to traditional methods

Benefits of using waterjet cutting for rubber, plastic and soft materials:

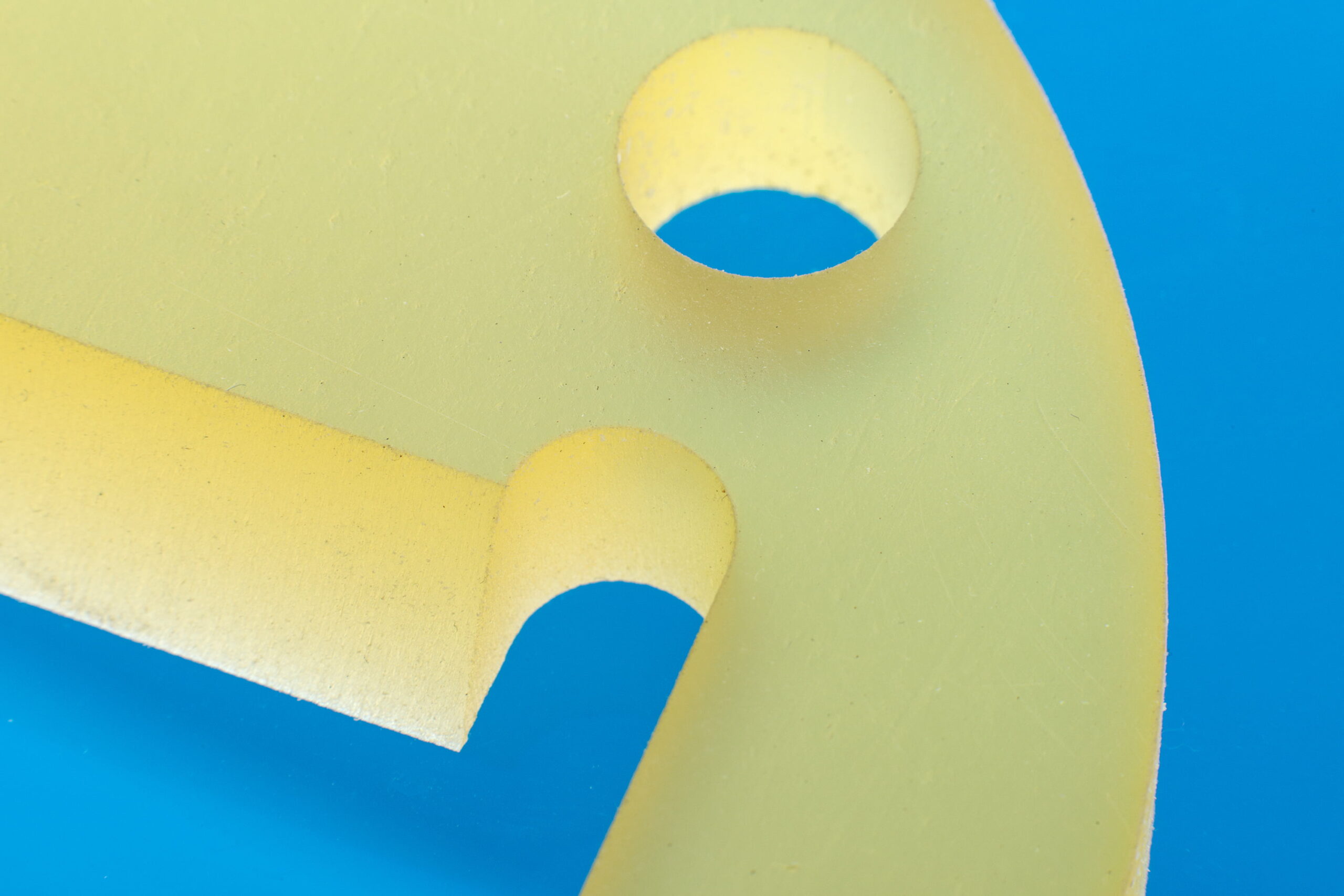

- High level of precision and intricate detail: The thin jet of water, often with a kerf of around 0.1 mm, allows complex shapes and detailed patterns to be created with meticulous accuracy.

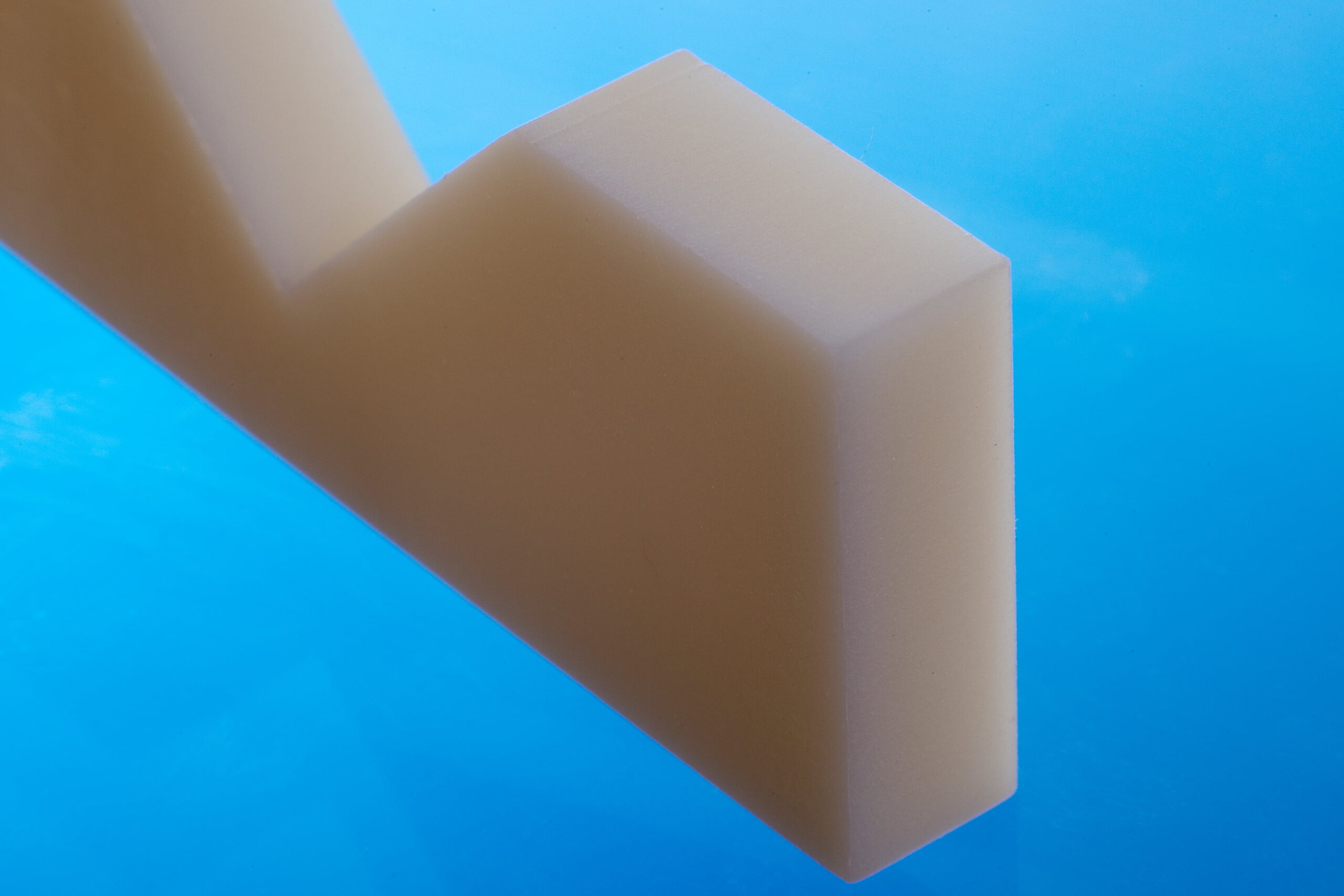

- No impact from heat: As waterjet cutting is a cold method, neither the structure nor the properties of the material are affected by heat, which prevents deformation or melting.

- Efficient use of materials: The ability to use shared cutting lines and stack multiple sheets of material during cutting minimises material waste and increases production efficiency.

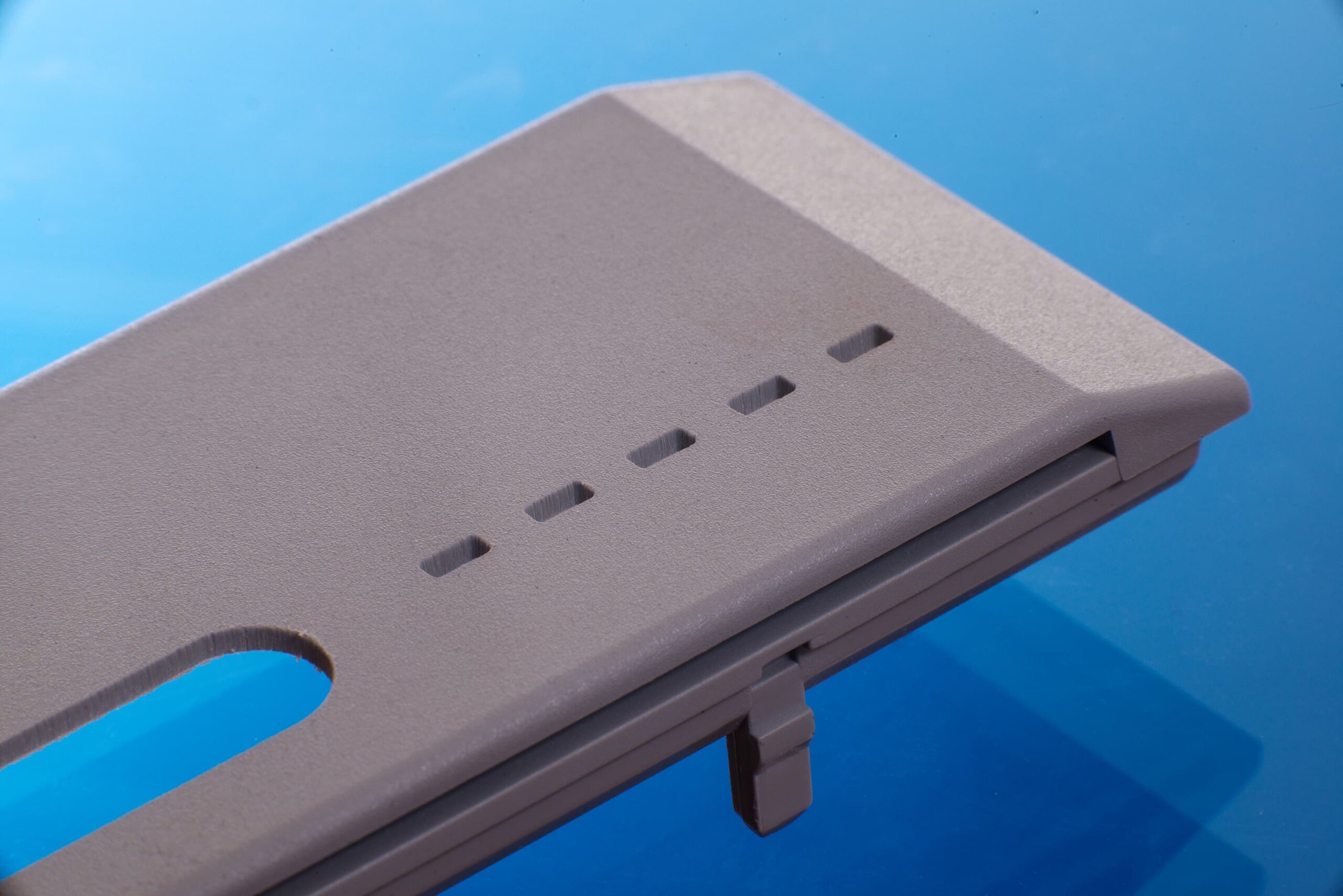

- Flexibility in production: A speedy conversion from drawing to finished product without the need for expensive tooling makes waterjet cutting ideal for both prototypes and small to medium-sized production batches.

Areas of application:

- Sealing and gasket industry: Manufacturing of gaskets and sealing materials with a high level of precision and quality.

- Insulation materials: Cutting of insulation materials for the construction and automotive industries.

- Packaging industry: Production of customised packaging solutions made of foam and plastic.

- Medical engineering: Manufacturing of components where meticulous precision and material integrity are essential.

Choosing waterjet cutting for rubber, plastics and other soft materials ensures an efficient, flexible and high-quality production process that meets today’s high demands for precision and material utilisation.

Question: How effective is waterjet cutting for plastic and rubber materials?

Answer: Waterjet cutting is very effective for both plastics and rubber, especially with pure waterjet cutting which produces thin kerfs of 0.1 mm without the use of abrasives. The method enables fast, precise cuts with minimal material impact. Multiple layers can be cut simultaneously, which increases productivity and reduces waste.

Question: What types of plastics and rubber can be cut with waterjet cutting?

Answer: Waterjet cutting can handle most types of plastic and rubber, including:

- Plastic: Acrylic (PMMA), polycarbonate (PC), polypropylene (PP), PVC, nylon (PA), PET and polyurethane (PU).

- Rubber: Silicone, neoprene, EPDM and butyl rubber.

It is a flexible method that is suitable for both soft and technically advanced materials.

Question: Is the quality of the plastic and rubber components affected by waterjet cutting?

Answer: No, waterjet cutting is a cold method that does not affect the properties of the material. It prevents melting, cracking and deformation. The result is a precise, high-quality kerf – whatever the thickness of the material.

Question: Is waterjet cutting cost-effective for large volumes of plastic and rubber parts?

Answer: Yes, especially given that the operator can stack materials, use shared cutting lines and multiple cutting heads. This reduces production time and material waste, making waterjet cutting a cost-effective option even for high-volume production.

Question: Which industries benefit from waterjet cutting for plastic and rubber applications?

Answer: Waterjet cutting is used by manufacturers of sealing materials, gaskets, disposable components and small and medium-sized batches in many industries where the precision of the shape and material quality are crucial.