Wood - Fabricated wood materials

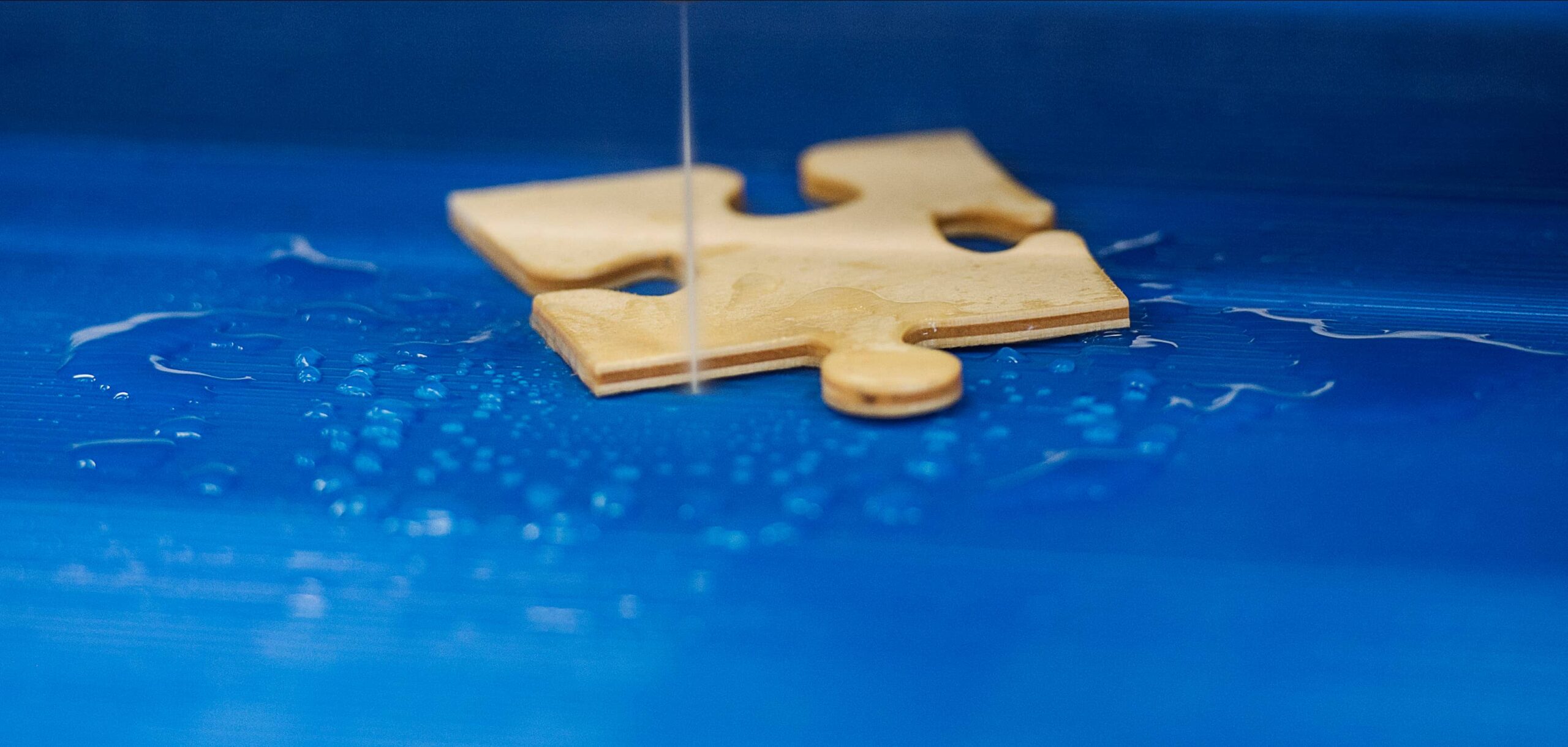

Waterjet cutting is an effective method for processing fabricated wood materials such as veneer and plywood. This technique offers several benefits that make it especially suitable for these materials.

Waterjet cuts fabricated wood materials, e.g. veneer and plywood

Benefits of using waterjet cutting for fabricated wood products:

- Fast set-up time: Waterjet cutting enables short preparation times, increasing production efficiency.

- Narrow width of cut: The thin jet of water produces minimal kerfs, which results in meticulous precision and minimises material waste.

- No chipping: Unlike traditional cutting methods, waterjet cutting minimises the risk of chipping, which is particularly important when cutting thin materials like veneer.

- Free-form cutting: The technique allows complex and creative shapes to be cut easily, without the need for specialised tools.

Historically, waterjet cutting has been used to make products such as wooden jigsaw puzzles, table-tennis racquets and doll-house furniture, which demonstrates its versatility in wood-working.

Areas of application:

- Shop fittings and exhibition stands: Creation of customised interior design details with a high level of precision.

- Advertising: Manufacturing of signs, letters and logos with intricate outlines.

- Toys and puzzles: Production of detailed wooden toys and puzzles with complex shapes.

- Table-tennis racquets: Precise cutting of components for sports equipment.

- Interior design details: Production of decorative features for furniture and interiors.

By using waterjet cutting for fabricated wood materials, manufacturers can achieve high-quality results with increased efficiency and flexibility.

Question: How effective is waterjet cutting for different types of wood and wood composites?

Answer: Waterjet cutting is effective for manufactured wood and wood composites such as MDF, plywood and veneer. It creates detailed cuts without producing heat or dust. The method is gentle on layered materials but can be slower than sawing, especially for high-density composites or thick wood panels.

Question: Does waterjet cutting affect the surface quality of the wood?

Answer: Yes, the surface quality can be affected depending on the type of wood, pressure and cutting speed. In some cases, further finishing work is required to achieve a completely smooth surface. The wood can also absorb moisture, which makes drying after cutting necessary to avoid swelling or deformation.

Question: Can waterjet cutting handle both thin veneers and thicker wood panels?

Answer: Yes, waterjet cutting can be used for both thin and thick wood materials. Thin veneers are cut with meticulous precision and no cracks arise. Thicker panels require pressure and speed adjustment and may need multi-stage cutting, which makes the process slower compared to conventional methods.

Question: Is waterjet cutting suitable for the production of complex wood items?

Answer: Yes, waterjet cutting is excellent for creating complex shapes and patterns in wood. The method is ideal for unique details and prototypes where precision is more important than speed. However, for mass production in thick wood, other methods may be more time-efficient.

Question: Which industries use waterjet cutting for working with wood?

Answer: Waterjet cutting is used in the furniture industry, interior design, construction, toy manufacturing, arts and shop-fitting. The method is popular for customised parts made of veneer, MDF and plywood, as well as for prototyping and small-scale manufacturing of decorative wood components.