Metals – Aluminum

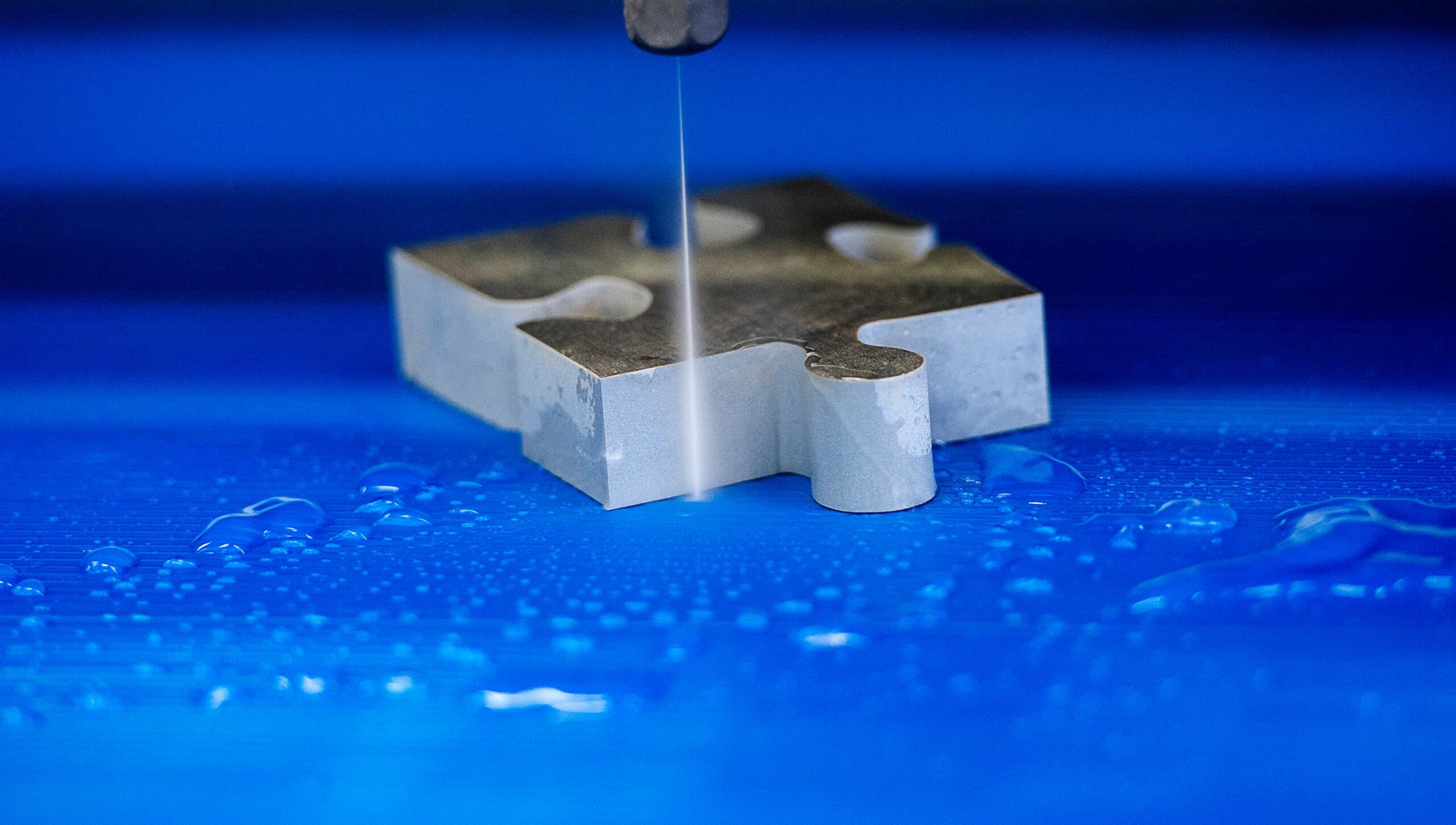

Waterjet cutting is an ideal method for working with aluminium, especially when the material's properties must be kept intact. This cold cutting technique does not affect the structure of the aluminium, so it is particularly useful in industries where precision and material quality are crucial.

Abrasive waterjets are ideally aluminum cutting

Benefits of using waterjet cutting for aluminium:

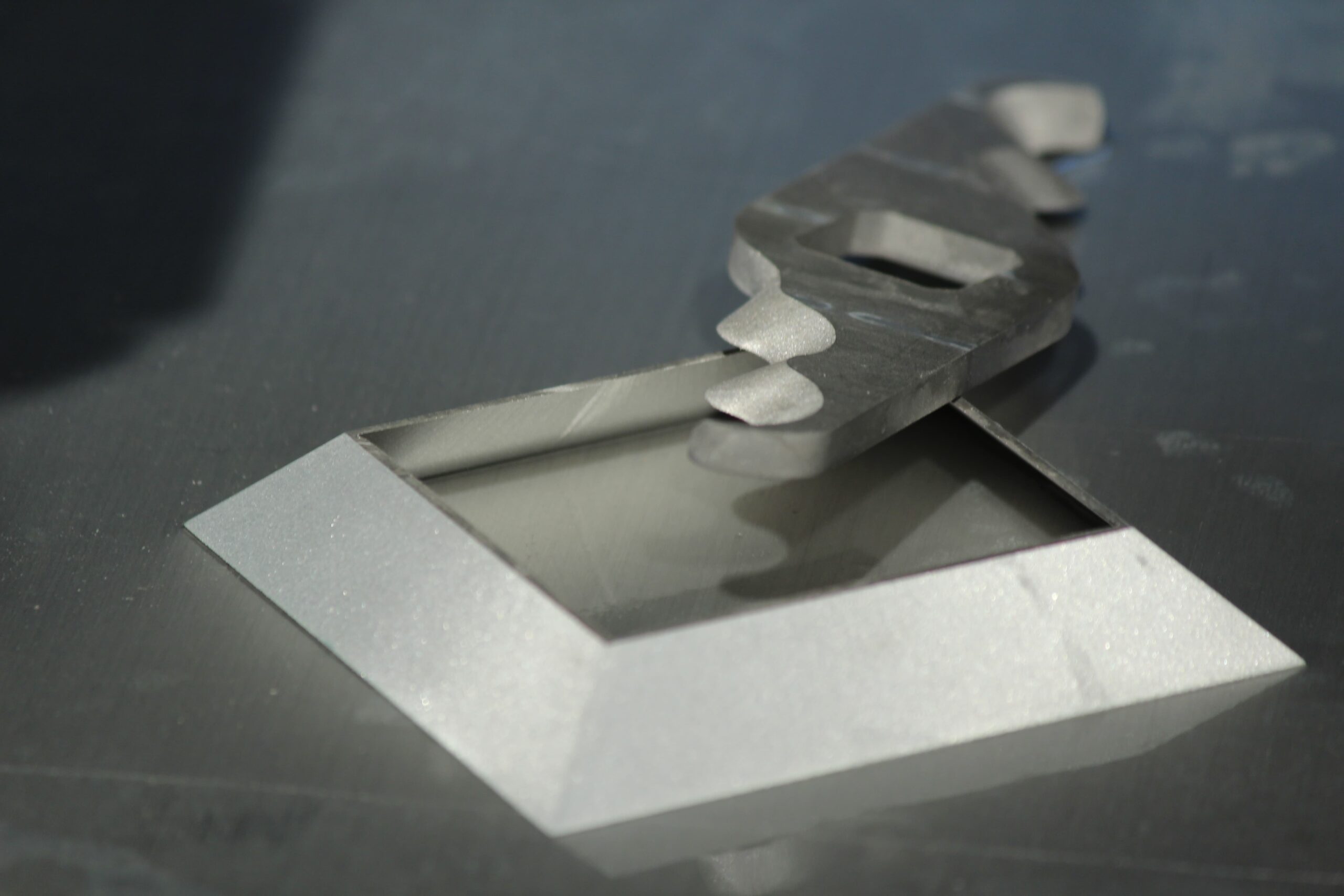

- Preserved material structure: As waterjet cutting is a cold method, it does not change the metallurgical properties of aluminium. This means that the material retains its original strength and shape after cutting

- No heat-affected zone: Unlike other cutting methods that can create heat-affected zones, waterjet cutting eliminates the risk of any thermal impact on the aluminium. This is particularly important for avoiding deformation or changes in the material’s properties.

- Environmentally friendly process: Waterjet cutting does not produce smoke or dust, which makes for a cleaner and safer working environment.

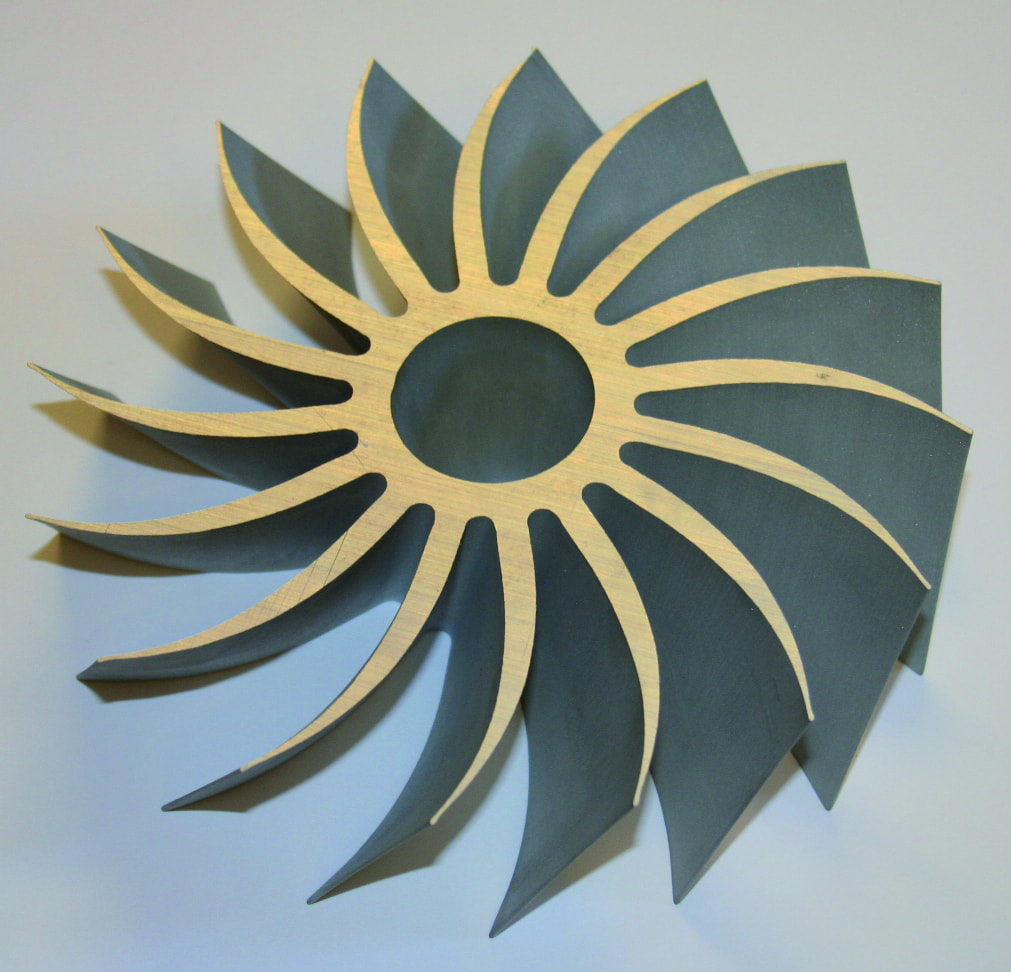

- Flexibility in thickness: Whether you need to cut thin aluminium sheets or thicker sections, waterjet cutting can handle different thicknesses with a high level of precision.

This method is therefore particularly suitable for applications in the aerospace and automotive industries, where a high level of accuracy and material integrity is required.

Question: What are the benefits of using waterjet cutting for aluminium?

Answer: Waterjet cutting produces clean and precise kerfs in aluminium without any impact from heat. The method reduces the risk of deformation, cracks and surface damage. It is suitable for all thicknesses, can handle complex shapes and does not usually require any further finishing work. It is also safe and environmentally friendly, and does not emit toxic gases or chemicals.

Question: How does waterjet cutting affect the material properties of aluminium?

Answer: As waterjet cutting is a cold method it does not change the structure or surface of the aluminium. There is no impact from heat, and the risk of mechanical defects such as buckling or cracking is very low.

Question: Can waterjet cutting handle thick aluminium sheets with a high level of precision?

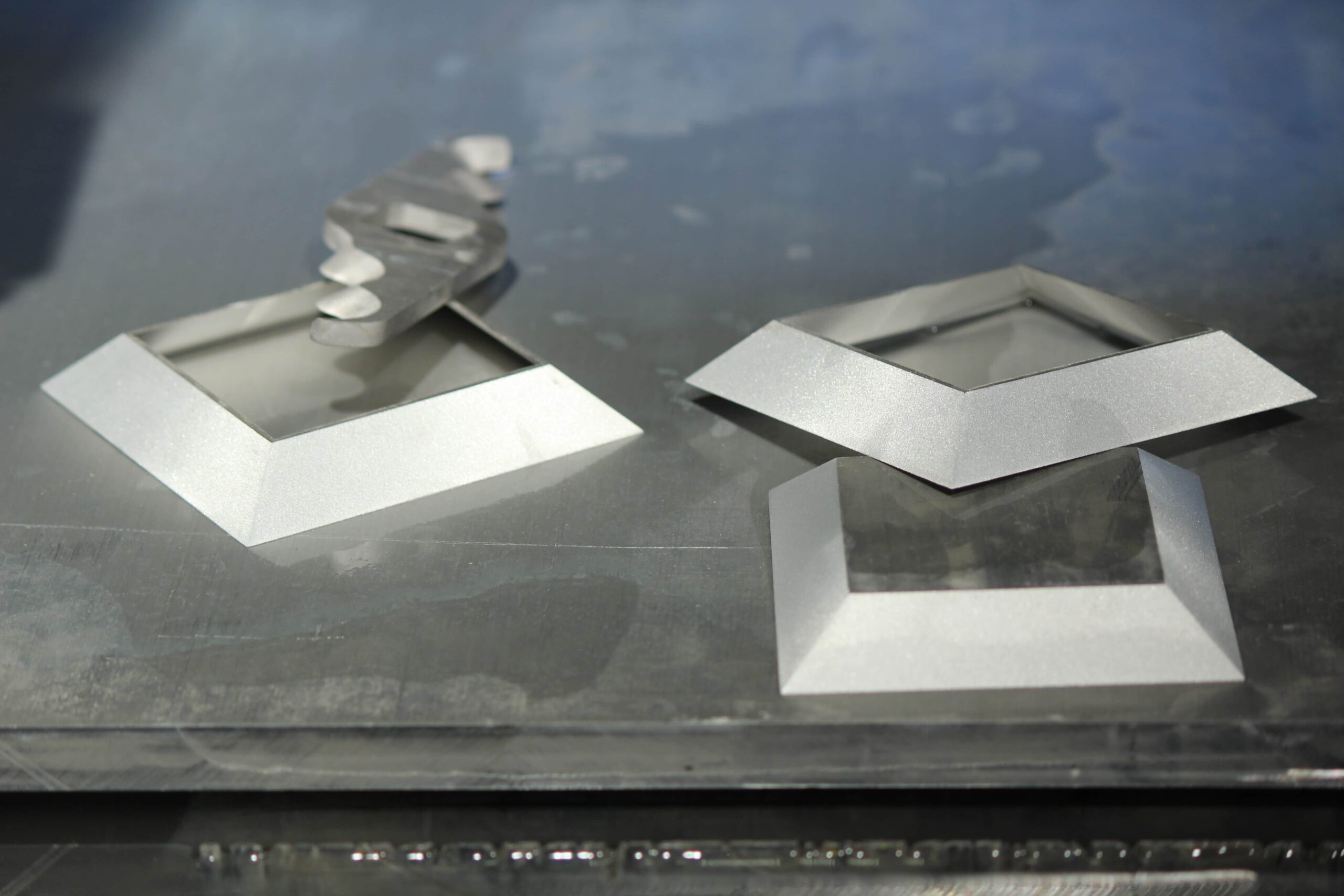

Answer: Yes, waterjet cutting can cut thick aluminium sheets – often several decimetres depending on the capacity of the machine – with meticulous precision. The right pressure, speed and abrasive settings ensure precise kerfs with minimal further finishing work required.

Question: Is waterjet cutting cost-effective for the production of aluminium components?

Answer: Waterjet cutting is cost-effective for the production of aluminium parts with complex shapes or tight tolerances. The method produces low material waste, which is economical when working with expensive materials. For high-volume production, other methods may be faster, but for precise, flexible manufacturing, waterjet cutting is often best.

Question: Which industries use waterjet cutting for aluminium applications?

Answer: Industries that use waterjet cutting for aluminium include automotive, motorsports, mechanical engineering, casting production, materials research and assembly parts manufacturing. It is also used for prototypes and small manufacturing batches that require meticulous precision.