Glass and acrylic glass

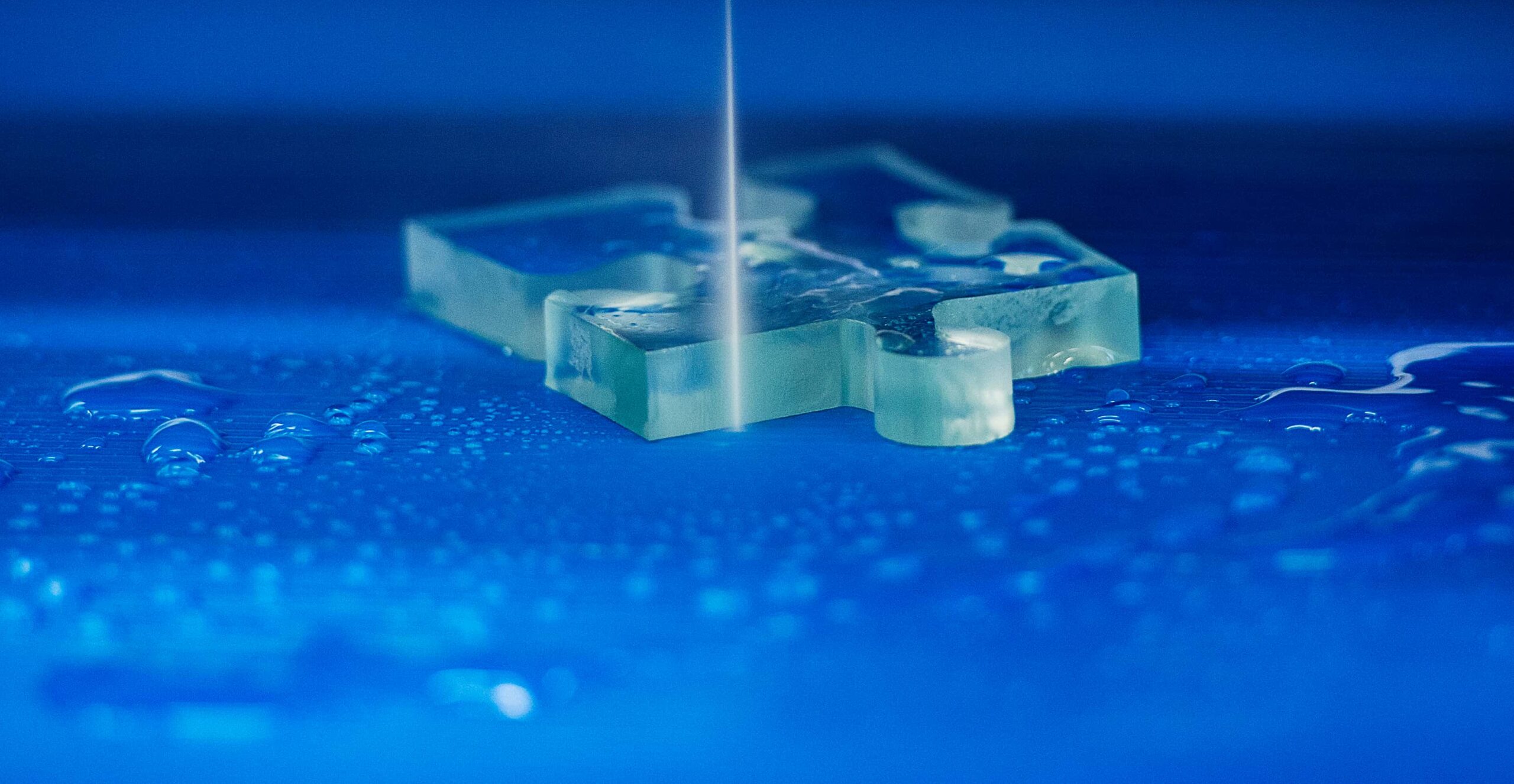

Waterjet cutting is an advanced and flexible method for cutting both glass and acrylic glass (Plexiglas). Using a high-pressure water jet, sometimes combined with abrasive particles, allows complex shapes and details to be cut with a high level of precision and without exposing the material to heat.

Cut any shape with waterjet technology

Benefits of using waterjet cutting for glass and acrylic glass:

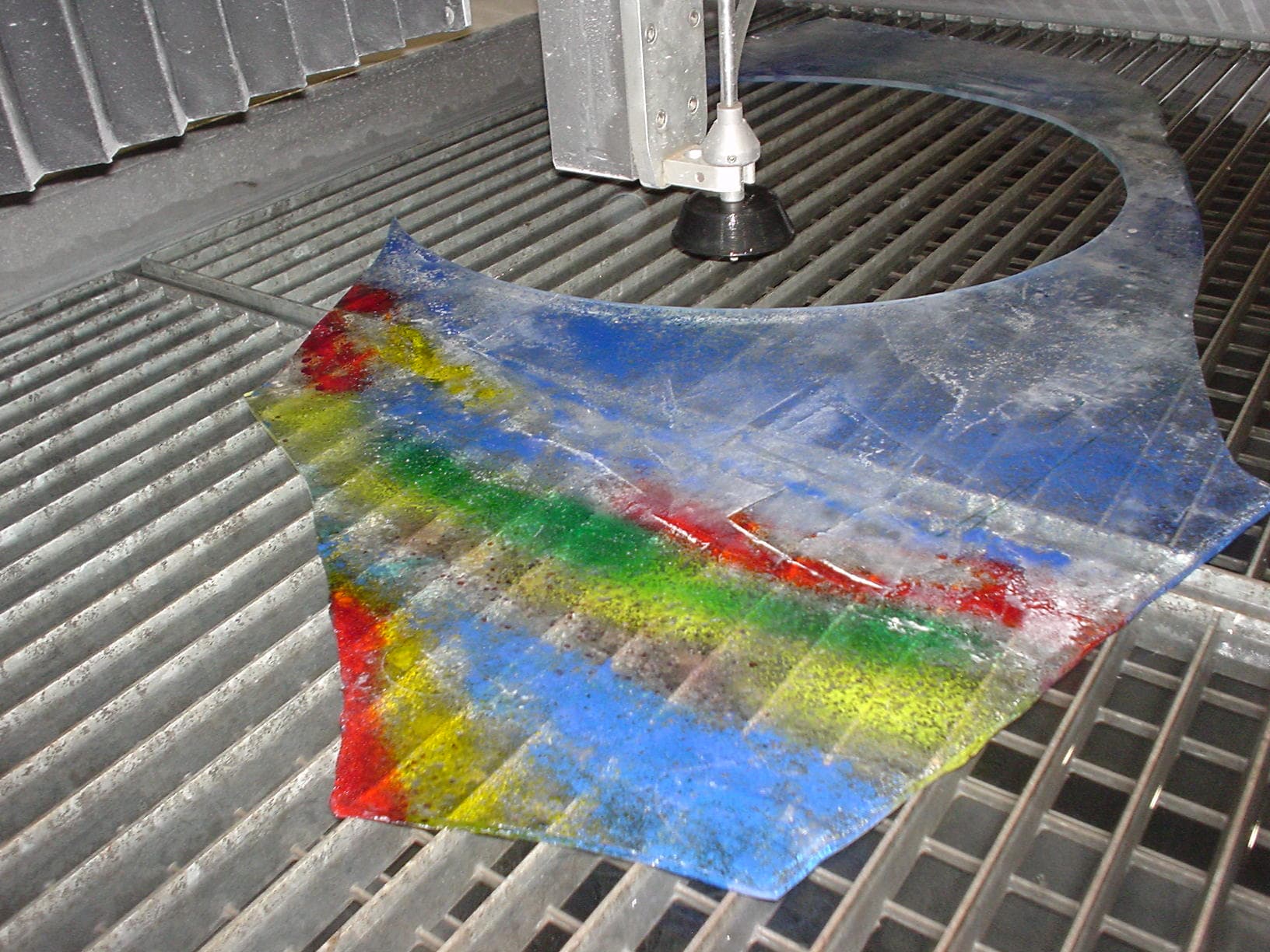

- High level of precision and intricate detail: Waterjet cutting can create intricate patterns and shapes with exact tolerances, which is particularly valuable for design and architectural applications.

- No impact from heat: As the process is cold, thermal impacts that could cause cracking or deformation in the material are avoided. This is particularly important when processing brittle materials like glass.

- Flexibility in material thickness: This method is effective for cutting both thin and thick materials, making it suitable for a variety of applications.

- Environmentally friendly process: Waterjet cutting does not produce any harmful fumes or dust, making for a better working environment and reduced environmental impact.

Areas of application:

- Construction and architecture: Manufacturing of glass components for façades, interiors and decorative elements.

- Interior design: Creation of unique furniture and interior design items in glass and acrylic glass.

- Advertising and signage: Production of signs, letters and logos with a high level of precision and quality.

- Automotive manufacturing: Manufacturing of glass and acrylic components for vehicles, including customised parts for luxury and special vehicles.

Choosing waterjet cutting for glass and acrylic glass ensures a high level of quality, precision and flexibility in production, making it the preferred choice in many industries.

Question: Is waterjet cutting a safe method for cutting different types of glass?

Answer: Yes, waterjet cutting is a gentle and safe method for working with most types of glass. The method uses a cold, abrasive jet of water that minimises the risk of cracks and thermal stresses. It is particularly suitable for thinner or medium-thickness glass. However, toughened glass can be more difficult to cut. For the best results, a high-quality abrasive is required.

Question: What is the risk of the glass cracking from waterjet cutting?

Answer: The risk of cracking is minimised by setting the cutting speed and water pressure correctly and using quality glass. By avoiding temperature shocks and using a controlled cutting technique, the integrity of the glass is preserved even with thin or brittle materials.

Question: Can waterjet cutting create complex shapes and patterns in glass?

Answer: Yes, waterjet cutting is ideal for creating intricate and complex designs in glass. The thin cutting jet allows for meticulous precision, which makes the method particularly suitable for artistic, architectural and technical glass applications.

Question: What advantages does waterjet cutting offer over traditional glass cutting methods?

Answer: Unlike mechanical or thermal methods, waterjet cutting is a cold process and does not cause heat cracks. It provides clean kerfs with a minimal need for further finishing work, handles thin and thick glass, and allows for extremely precise and complex shapes – perfect for high-quality glass processing.

Question: Which industries use waterjet cutting for glass applications?

Answer: Waterjet cutting is used in the glass industry, construction, automotive, electronics, packaging, medical engineering and art and design. The method is particularly popular for work requiring a high level of precision and scratch-free processing.