Edgecut (Panel One HMI)

A modern way to operate a CNC Waterjet Machine

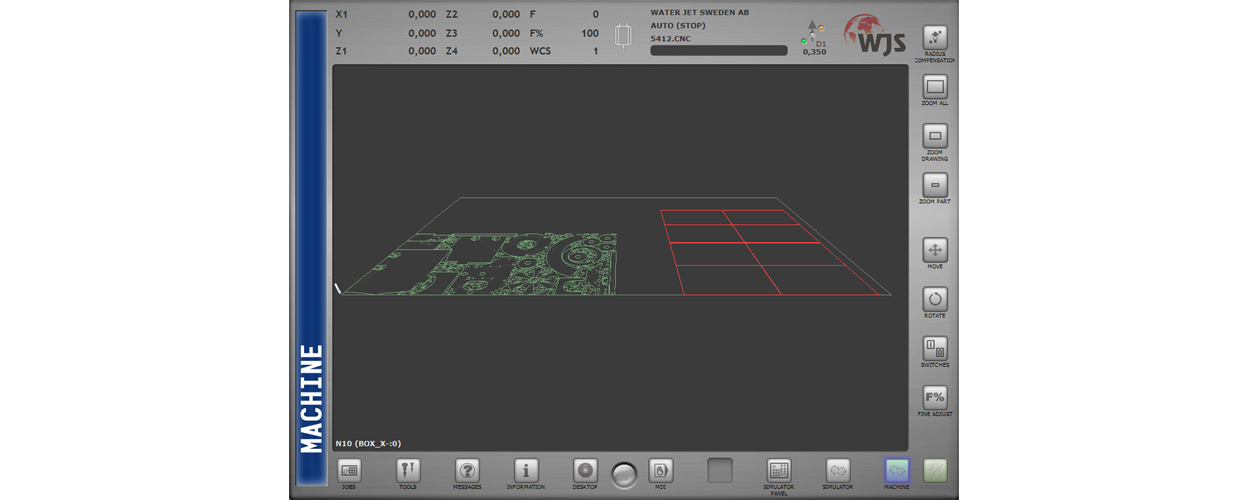

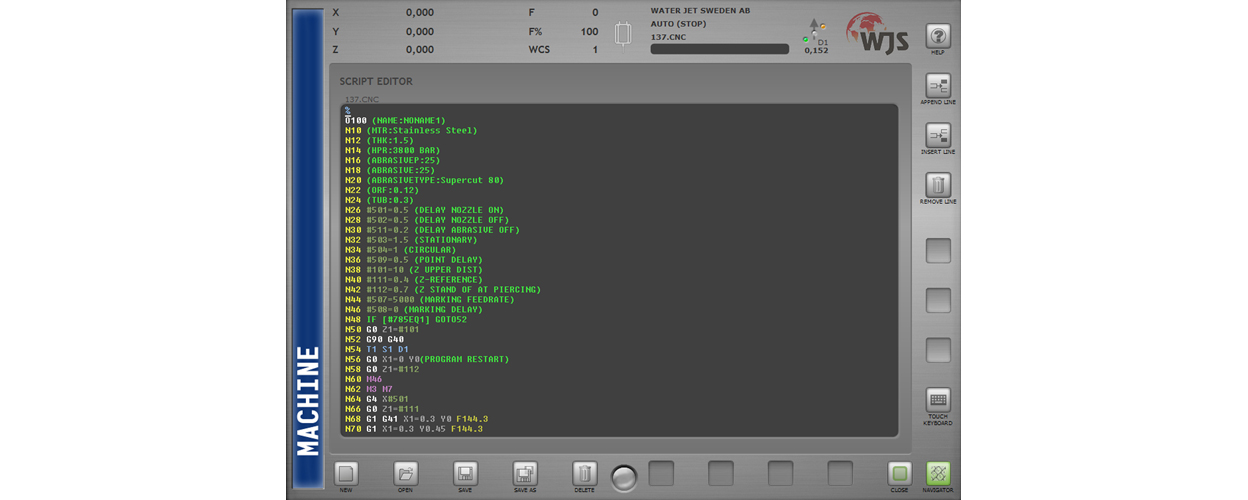

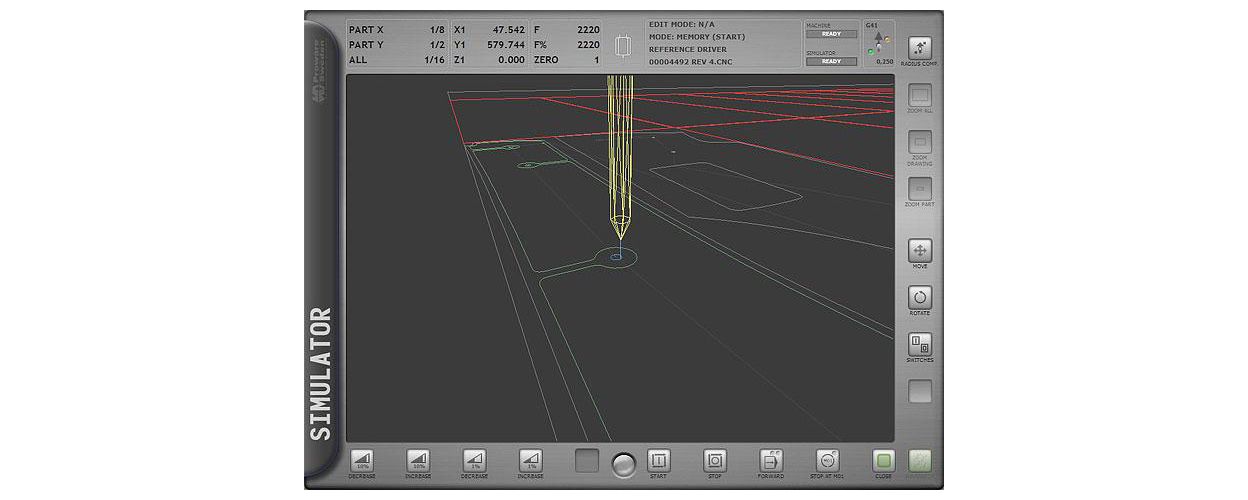

Edgecut software in PanelOne® HMI is the operator interface for all Select and Special machine models. Edgecut SW is a modern way to operate your CNC-machine. With a clean design and user-friendly interface that is quick to learn and easy to manage. You rotate, pan and move around freely and can see the job with a built-in automatic tool follow function.

Edgecut Features

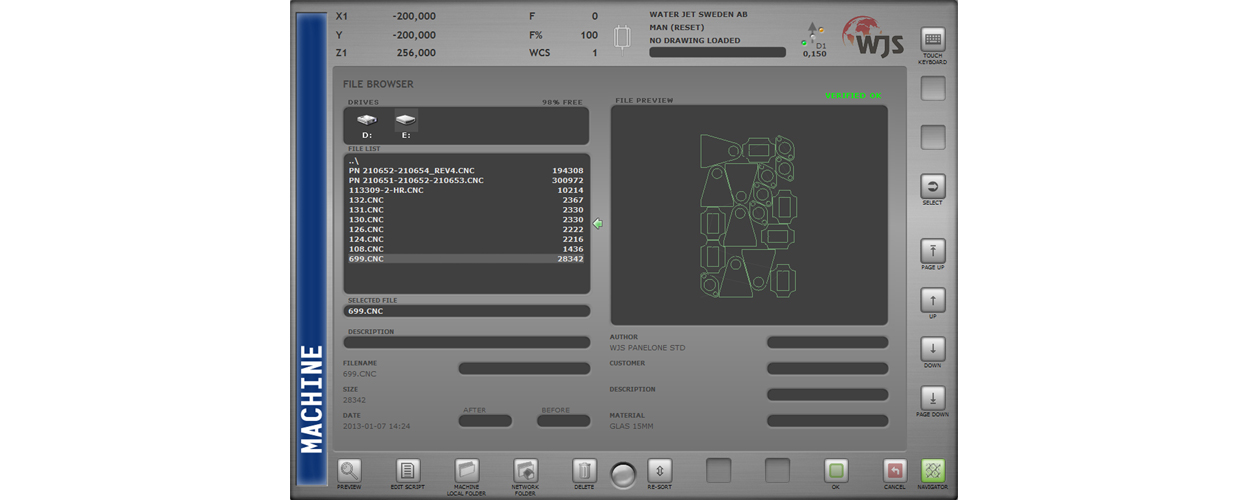

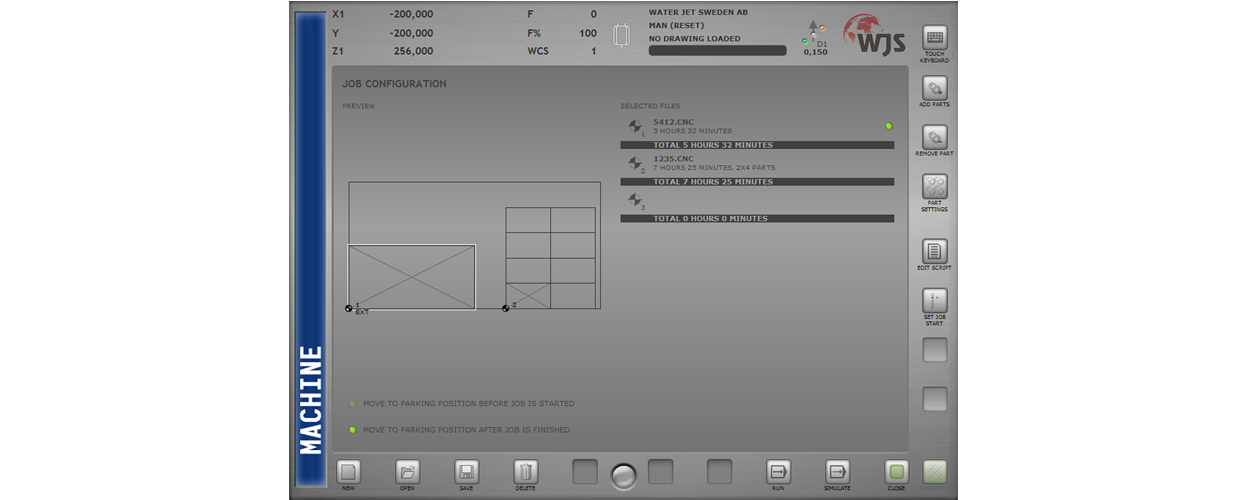

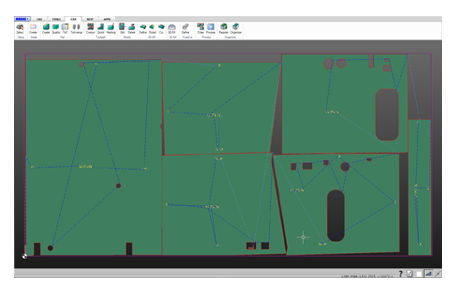

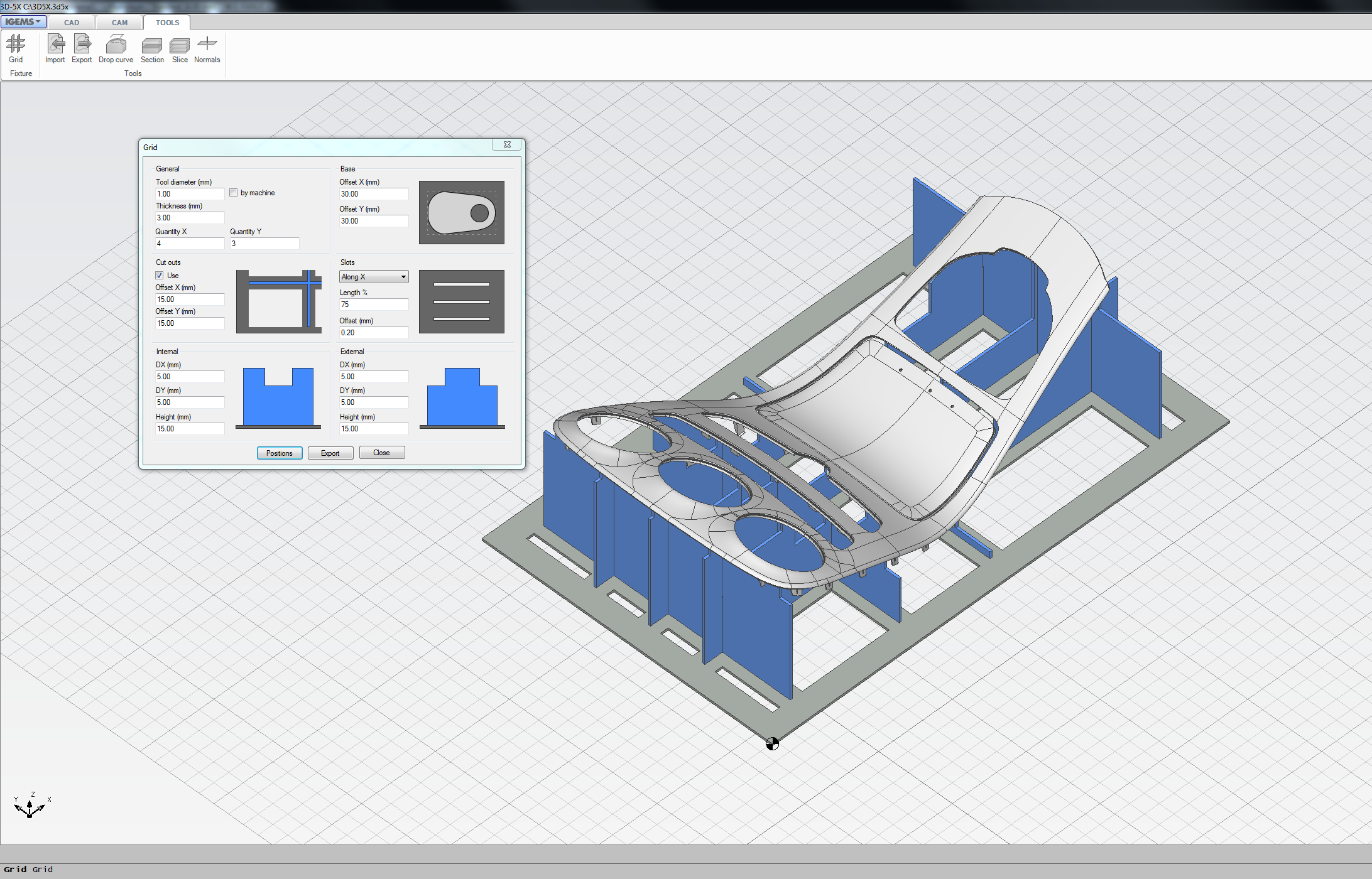

Job Management – One job can handle up to six zero points. Ten part programs can be assigned for each zero point. Save jobs to be used later, includes all data for zero points etc. Direct program scrip verification. Estimated time/direct feedback from override. Multipart function (Part grid nest). Add, edit and save parking positions. Job simulator: Prepare and simulate a job while the machine is operating and more.

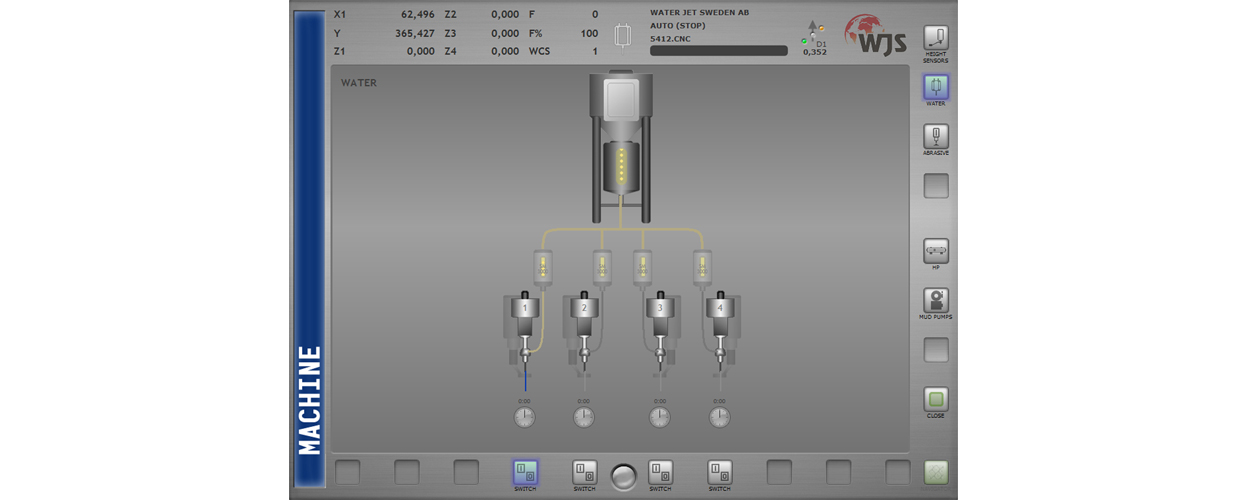

Tool Management – Easy overview of all tool settings. Advanced tool handling including wear timers. Online radius compensation. Part quality optimization by using up to five compensation values. Many tool configurations are set automatically by the CNC script

Operations functions – there is a long list of practical and time saving operational functions available in the Edgecut HMI Software

- Retrace: Reveres the cutting direction

- Reposition function: Stop cutting cycle, move manually away to measure the part etc.

- Program restart: Restart when the cutting cycle have been aborted

- Dry run function: Dry run test or restart

- Online working height compensation (If no height sensor is used)

- Adaptive calculated cycle time

- Real-time federate calculation

- Cutting head and abrasive feeder service test, and manual scrap off cut

- MDI: Execution of simple machine commands

Services – Online diagnostics, total Machine time/Service intervals, operator messages/alarms and feedback from the machine. Alos service mode lock out (safety mode for a quick and safe restart) and logbook for CNC, PMC, alarms, messages

Contact

Five year performance warranty

We guarantee that all our machines keep the same tolerance level after five years as when the machine was first delivered.

Lifetime support by waterjet specialists

Our service team is highly specialized within the field of water jet cutting. Via our hotline support, our technical expertise is available on a 24/7 basis.

Klas Wallström

CMO

Sweden

Welcome

If you have questions, please call us at +46 457 455 440 or fill in the contact form and we will get in touch.