Abrasive Supply Systems

Enabling any level of productivity

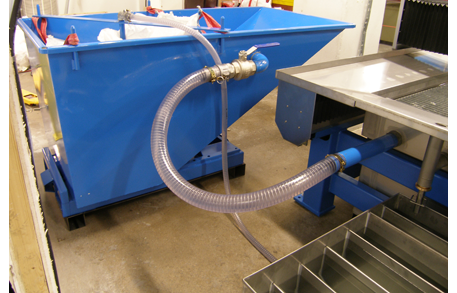

Abrasive Pressure Vessel – The pressure vessel has a 200l capacity (About 480 Kg with Australian or Indian Garnet 80 Mesh). With sensors for low level and empty pressure vessel, the operator sees status direct on machine panel.

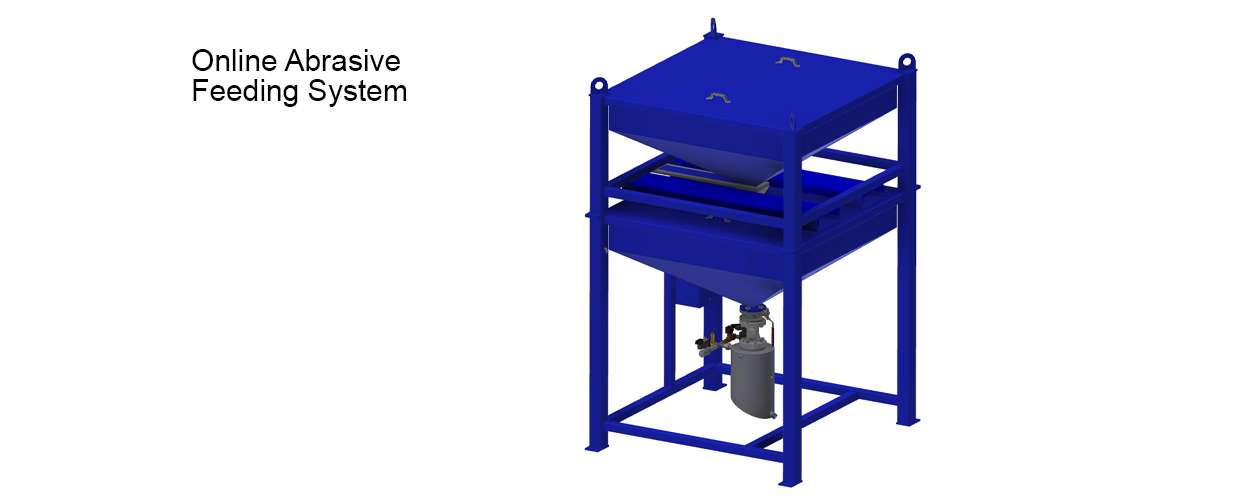

Abrasive Tower– For quick and easy replenishment of the abrasive pressure vessel. Choose between a “ONE TON” or “TWO TON” version. The ONTE TON TOWER is designed for a one ton “big bag” and has a maximum volume of 700L or 1600 kg abrasive. The TWO TON TOWER is designed for a two ton “big bag”, and has a maximum volume of 1150L or 2500 kg abrasive.

Online Abrasive Feeding System – The online feeding system is used for continuous supply of natural abrasives to the machine, for cutting 24/7.

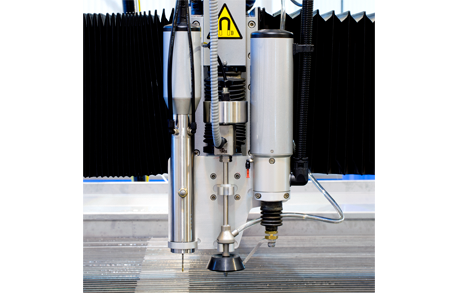

Abrasive Feeder SM 3000 – The abrasive feeder is mounted on the cutting unit. SM3000 is a dosage feeder and the abrasive flow is modified by using orifice washers with different diameters. The abrasive feeder is equipped with electronic sensors to detect abrasive starvation or a blockage. The SM 3000 abrasive feeder improves efficiency and reduces costs.

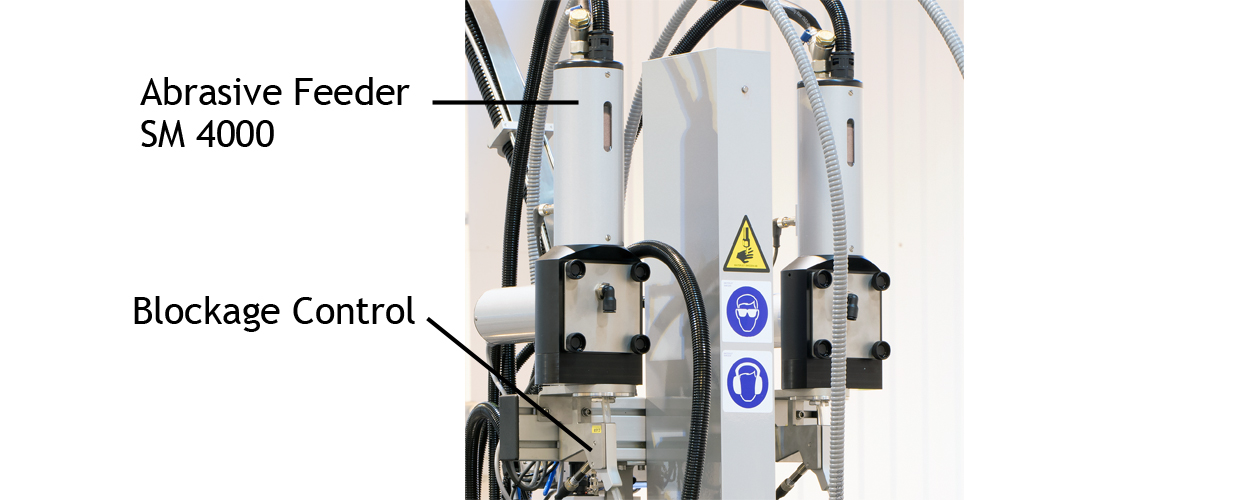

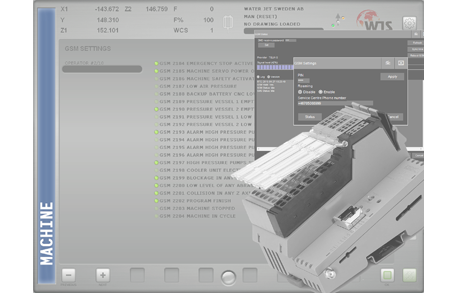

Electronic Abrasive SM 4000 – The abrasive feeder SM 4000 is an electronic abrasive feeder where the abrasive flow is controlled from the PanelOne operating software. The abrasive feeder is equipped with electronic sensors to detect abrasive starvation or a blockage.

Contact

Five year performance warranty

We guarantee that all our machines keep the same tolerance level after five years as when the machine was first delivered.

Lifetime support by waterjet specialists

Our service team is highly specialized within the field of water jet cutting. Via our hotline support, our technical expertise is available on a 24/7 basis.

Klas Wallström

CMO

Sweden

Welcome

If you have questions, please call us at +46 457 455 440 or fill in the contact form and we will get in touch.