WJS machine move to new workshop after ten years of stable performance

Here is a news article from our Chinese subsidiary WJS Pacific Trading Company in Beijing. It tells the story of a complicated but successful relocation of a well-maintained, 10-year-old machine system. Machine relocation is a service that is available to all Water Jet Sweden’s customers around the world. If you need to relocate, we help you minimize downtime and take overall responsibility from start to finish – from pre-inspection, dismantling, transport, assembly, installation to performance measurement and test cutting.

“Our model NCG3040S with the most cutting-edge technological concepts has been serving customer Xuchang Tobacco Machinery Ltd over ten years now. The customer is top tobacco machinery company in China. The machine is first WJS machine equipped with 6000bar pump in China market. Thanks to the customer’s insistence on formal maintenance according to the original manufacturer’s instruction, the machine has always performed very stably. Satisfied with smooth performance, customer decided to move this equipment as a key device to their new workshop.

Due to the limited space conditions of the site, the machine cannot be moved as a whole one to the new site. Only way is disassembling the main frame before transportation. This is a challenge for maintaining the accuracy of the equipment after disassembly and assembly. At the same time, due to the fact that the equipment is the key equipment, the time allowed for relocation is also very limited. Therefore, when disassembling, it is necessary to consider minimizing the cable connection work during installation, which is even more difficult than installing a new machine. All Engineers of WJS Pacific are accomplished and have been rigorous trained at WJS headquarter in Sweden. With rich experience and solid professional knowledge, they are always able to meet the needs of customers.

According to the complex situation of this project, our service engineer went to customer site in advance to carefully study the site space conditions, and made a reasonable technical plan. The plan includes the auxiliary support fixtures to be used during the relocation process, the components that need to be replaced during the relocation process, and the layout of the equipment on new site. The technical solution got substantial support from technical service team at WJS headquarter. The plan will refine the implementation details to every day, ensuring that customer can smoothly back to normal production within the scheduled time. With the active cooperation of the customer, the auxiliary support fixtures were prepared on time as required. The spare parts delivered from WJS headquarter also arrived as scheduled. The relocation work was fully carried out according to customer expectations from the last week before the National Day holiday.

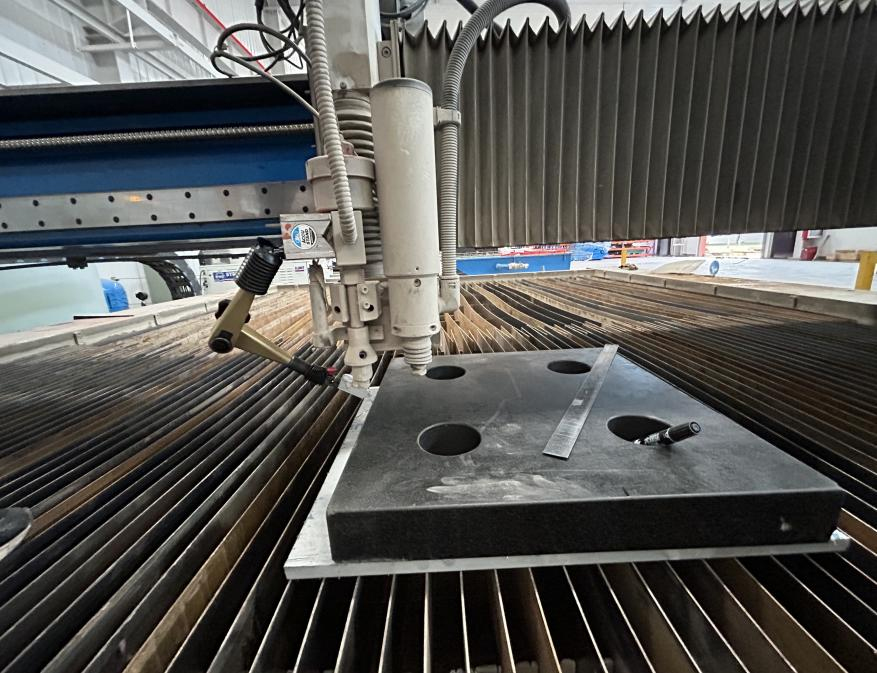

Accuracy detection during installation

After the installation of the machine, our engineers inspect and restore each accuracy data according to the manufacturer’s instruction. The accuracy has reached the same level as it just delivered. This fully demonstrates that the WJS water cutting machine has fully considered the long-term stability of accuracy from both the design and manufacturing perspectives.

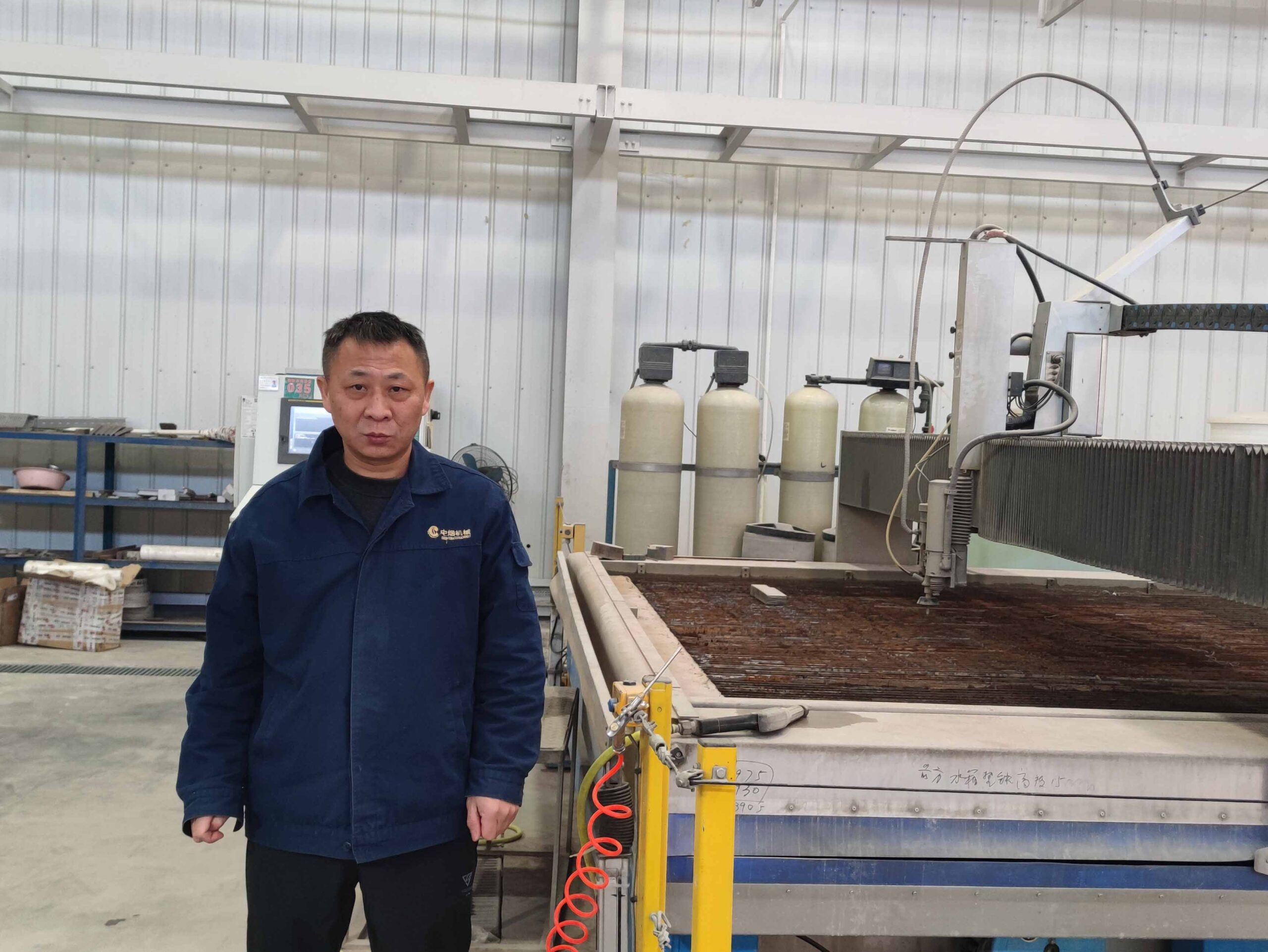

Operator is happy with the machine on new site

All work, including one day of accompanying production on site, was successfully completed within one week. Rich experience and strong on-site skill of our engineers have been once again verified to be trustworthy.

By: Eric Wei, Water Jet Sweden Pacific Trading Company Ltd.