Metals - Ferrous Metals

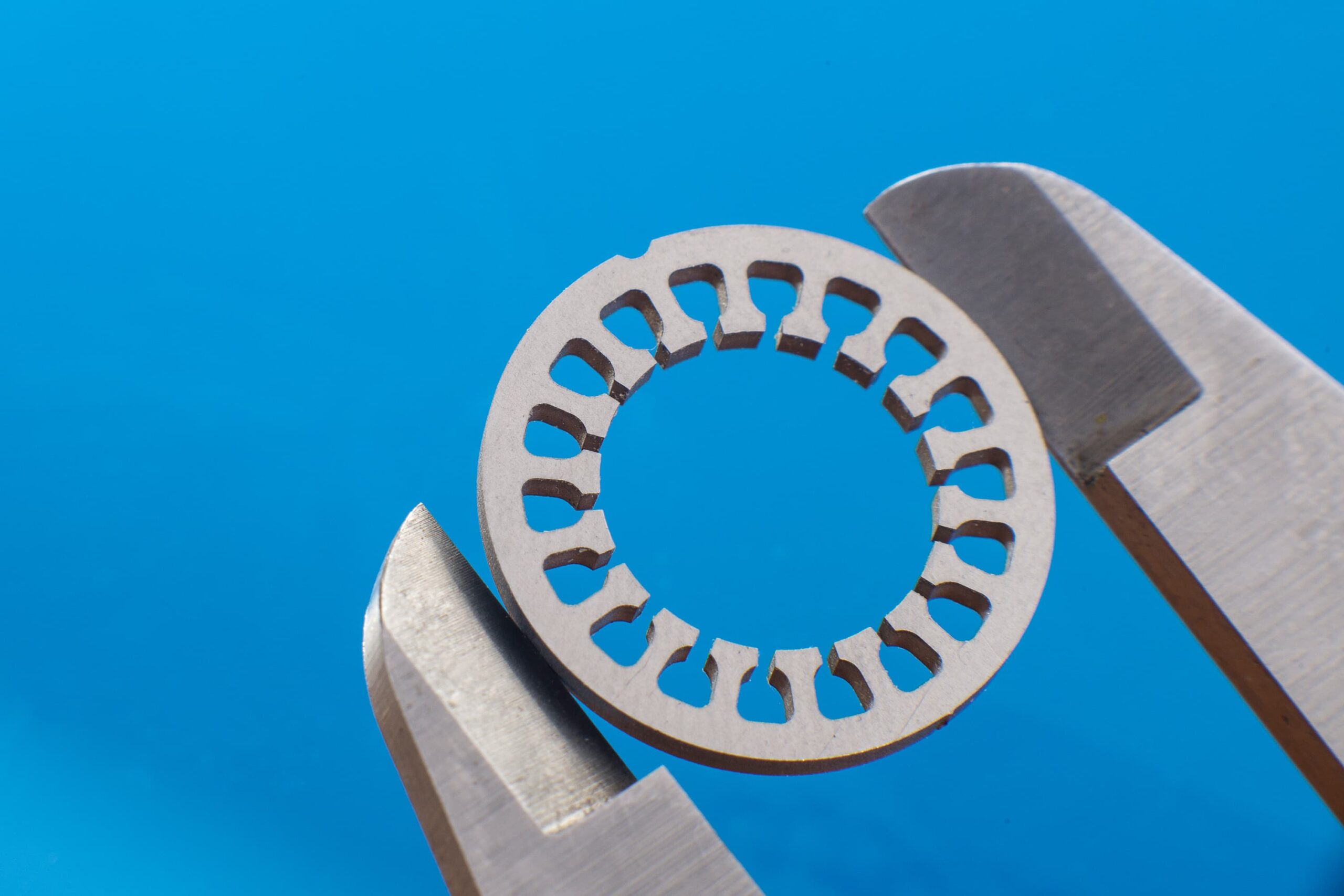

Abrasive waterjet cutting is a versatile and effective method for cutting ferrous metals, including stainless steel, tool steel and various steel alloys. Whether you need to cut 10 mm thick stainless steel or a 100 mm thick titanium alloy, waterjet cutting offers a high level of precision and flexibility for a range of materials and thicknesses.

Abrasive waterjets are ideally suited for tough metal cutting

Ferrous metals commonly processed using waterjet cutting:

- Cast iron

- Wrought iron

- Stainless steel

- Tool steel

- Alloy steels such as Hastelloy, Hardox, Inconel, Monel and Duplex steels

Benefits of using waterjet cutting for metals:

- No heat-affected zone: Waterjet cutting is a cold method that eliminates the risk of thermal impact, thus preserving the original properties of the material without it hardening or deforming at the face of the cut.

- Versatility: Ability to cut through all types of alloys, including high-resistance and heat-sensitive materials, without compromising quality.

- High level of precision: The narrow kerf allows intricate and complex shapes to be cut with minimal material loss, which is particularly beneficial for advanced design requirements.

- Environmentally friendly process: As no smoke or harmful vapours are emitted during the process, waterjet cutting makes for a cleaner and safer working environment.

- Reduced need for fixtures: The low lateral and vertical forces during cutting minimise the need for extensive clamping, which simplifies set-up and saves time.

- Processing of thick materials: Waterjet cutting can cut thicker materials than laser technology and offers more precise cutting compared to plasma or flame-cutting processes.

Choosing abrasive waterjet cutting for ferrous metals ensures efficient, precise and environmentally friendly production that meets high standards of quality.

Question: How suitable is waterjet cutting for different ferrous metals such as stainless steel and wrought iron?

Answer: Waterjet cutting uses a high-pressure jet of water mixed with abrasive particles to cut through materials such as stainless steel and wrought iron. This method allows precise kerfs without any impact from heat, which preserves the original properties of the material.

Question: What are the benefits of waterjet cutting compared to thermal cutting methods for metals?

Answer: Waterjet cutting is a cold method that eliminates heat-related deformations and maintains the integrity of the material. The face of the cut is smooth with a high level of precision, reducing the need for finishing work afterwards. In addition, waterjet cutting does not produce any toxic gases, which makes it environmentally friendly and safe for operators.

Question: How does waterjet cutting affect the surface quality of the metal and the need for finishing work afterwards?

Answer: Waterjet cutting produces a very clean and smooth face of the cut, often eliminating the need for further finishing work. This precision is particularly beneficial when processing delicate materials that can be difficult to finish afterwards.

Question: Which industries benefit from waterjet cutting for metal-working?

Answer: Several industries use waterjet cutting for metal-working, including:

- Aerospace industry

- Automotive industry

- Motorsports

- Mechanics workshops

- Tool making

- Precision engineering and medical engineering

- Materials research

- Steel construction