Upgrade your 2D cutting with Alphajet® TVL

Alphajet® TVL is the new generation of mechatronics for vertical cutting. With a design of 45-30-30 mechatronics, fixed TCP, and low rotation point, only very small, precise movements are required to achieve a perpendicular cut. The concept of TVL includes three functions that compensate for the dynamics of the waterjet cutting process, TAC, VOC and LAG.

Quick and easy upgrade

The Alphajet® TVL can handle both 4100 and 6200 bar water pressure. An upgrade from 2D to Alphajet® TVL cutting tools includes the Alphajet unit, software upgrades, any new hardware needed, installation, commissioning, performance measurement and user training. To minimize downtime, we deliver Alphajet® pre-assembled. Installation and commissioning take about two business days and one day of user training.

The main requirement for the upgrade is a machine with a 4-axis Fanuc-CNC control with PanelOne®. On older machines, the control system can also be upgraded.

TVL functions explained

The TVL functions compensate for the dynamic properties if the waterjet cutting process.

TAC (Taper Angle Control)

TAC (Taper Angle Control)

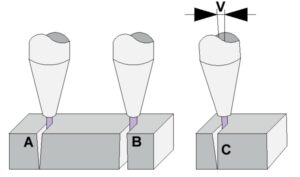

The TAC controls the incision size of the bottom side of the part. To be able to make a vertical cut and correct measurements the jet need to be tilted in different directions. With a fast-cutting speed (A), the jet will make a conical cut. On example B the speed is slower, getting a wider bottom. At C the jet is tilted with the angle of V and one side becomes vertical.

VOC (Variable Offset Control)

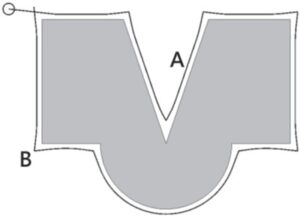

The VOC controls the size of the top side of the part. The jet will remove more material when you cut with a slow speed than when you cut with a fast speed. To obtain correct measurements the VOC change the kerf depending on the actual cutting speed. In the picture the kerf is smaller at A and wider at B since the speed is faster at this point.

The VOC controls the size of the top side of the part. The jet will remove more material when you cut with a slow speed than when you cut with a fast speed. To obtain correct measurements the VOC change the kerf depending on the actual cutting speed. In the picture the kerf is smaller at A and wider at B since the speed is faster at this point.

LAG (Lag Control)

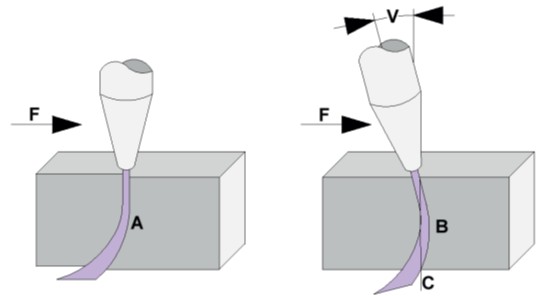

When cutting through the material the jet on the down side will be reflected opposite to the cutting direction F. The reflection is called the LAG. The LAG will increase with a faster cutting speed than with a low speed. Lag Control means that the cutting angle V is adjusted so the front position on the topside is perpendicular to the front position on the bottom side (B and C)

When cutting through the material the jet on the down side will be reflected opposite to the cutting direction F. The reflection is called the LAG. The LAG will increase with a faster cutting speed than with a low speed. Lag Control means that the cutting angle V is adjusted so the front position on the topside is perpendicular to the front position on the bottom side (B and C)

Contact us for more information and a quote.

Contact

Phone: +46 457 455 445

E-Mail: service@waterjet.se