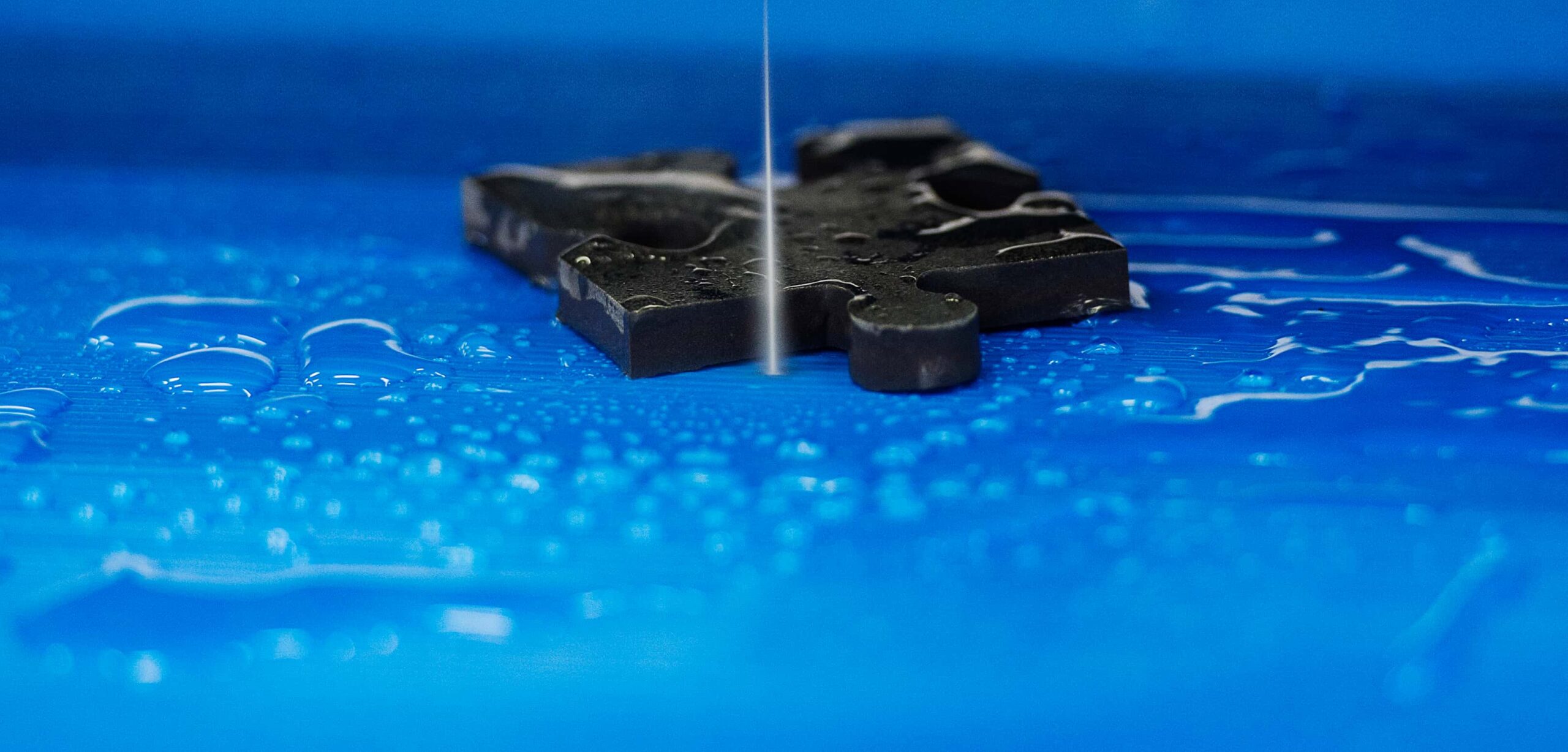

Stone, tiles and other ceramic materials

Waterjet cutting is an ideal method for cutting hard and brittle materials such as stone, tiles and other ceramic products. This technique uses a high-pressure jet of water, often combined with abrasive materials, to cut through the material with a high level of precision without causing cracks or damage.

For architectural design and artistic work

Benefits of using waterjet cutting for stone and ceramic materials:

- High level of precision: It enables the creation of complex and detailed patterns, which is particularly useful in architectural design and artistic projects.

- No impact from heat: As waterjet cutting is a cold method, the risk of thermal damage that can cause cracks or deformations in the material is eliminated.

- Clean working environment: The method does not generate any dust or harmful vapours, which makes for a safer and cleaner working environment.

- Material savings: The narrow kerf minimises material waste and enables efficient use of raw materials, which can lead to cost savings.

- Versatility: Waterjet cutting can be used on a wide variety of materials, including stone, tiles and ceramics, making it a flexible solution for different projects.

Areas of application:

- Building features: Cutting of floor tiles, wall cladding, stairs, window sills and decorative inlays in materials such as marble and granite.

- Interior design: Manufacturing furniture, kitchen counters and table tops with precise dimensions and unique designs.

- Artistic projects: Creation of mosaics, ornaments and other artistic works in natural or artificial stone.

- Tile installations: Precise cutting of tiles and floor tiles to fit specific design requirements or to make cut-outs for pipes and fittings.

By using waterjet cutting for stone, tiles and ceramic materials, high-quality results can be achieved efficiently and with a high level of precision, making it the preferred method in both industrial and creative sectors.

Question: What are the benefits of using waterjet cutting for stone and ceramic materials?

Answer: Waterjet cutting produces precise kerfs in hard materials such as granite, marble and ceramics – without dust or heat build-up. It requires minimal clamping, minimises scrapping and enables intricate patterns. The technique increases productivity and reduces tooling costs thanks to its universal and gentle cutting tool.

Question: Can waterjet cutting handle hard materials such as granite and marble with a high level of precision?

Answer: Yes, waterjet cutting can be used for hard materials such as granite and marble with meticulous precision. Using abrasive water and CNC control, complex shapes can be created without the occurrence of cracking or deformation. It is a popular method in construction and design projects that require precise and clean kerfs.

Question: What is the risk of the ceramic material cracking from waterjet cutting?

Answer: Waterjet cutting minimises the risk of cracking when the pressure, speed and temperature are set correctly. As it is a cold and non-contact method, the ceramics are not affected by thermal stress – making the technique safe for brittle materials.

Question: Is waterjet cutting cost-effective for the production of stone and ceramic components?

Answer: For small to medium-sized batches, where precision and low material loss are crucial, waterjet cutting is often a cost-effective choice. The method minimises the need for further finishing work and provides high material utilisation. However, for large-scale production, an individual cost analysis should be carried out.

Question: Which industries benefit from waterjet cutting for stone and ceramic applications?

Answer: Waterjet cutting is used in the construction, design, art, electronics and aerospace industries. It is suitable for everything from tiles and façade cladding to natural stone engraving and advanced ceramic components in high-tech applications.