Metals – Other non-ferrous metals

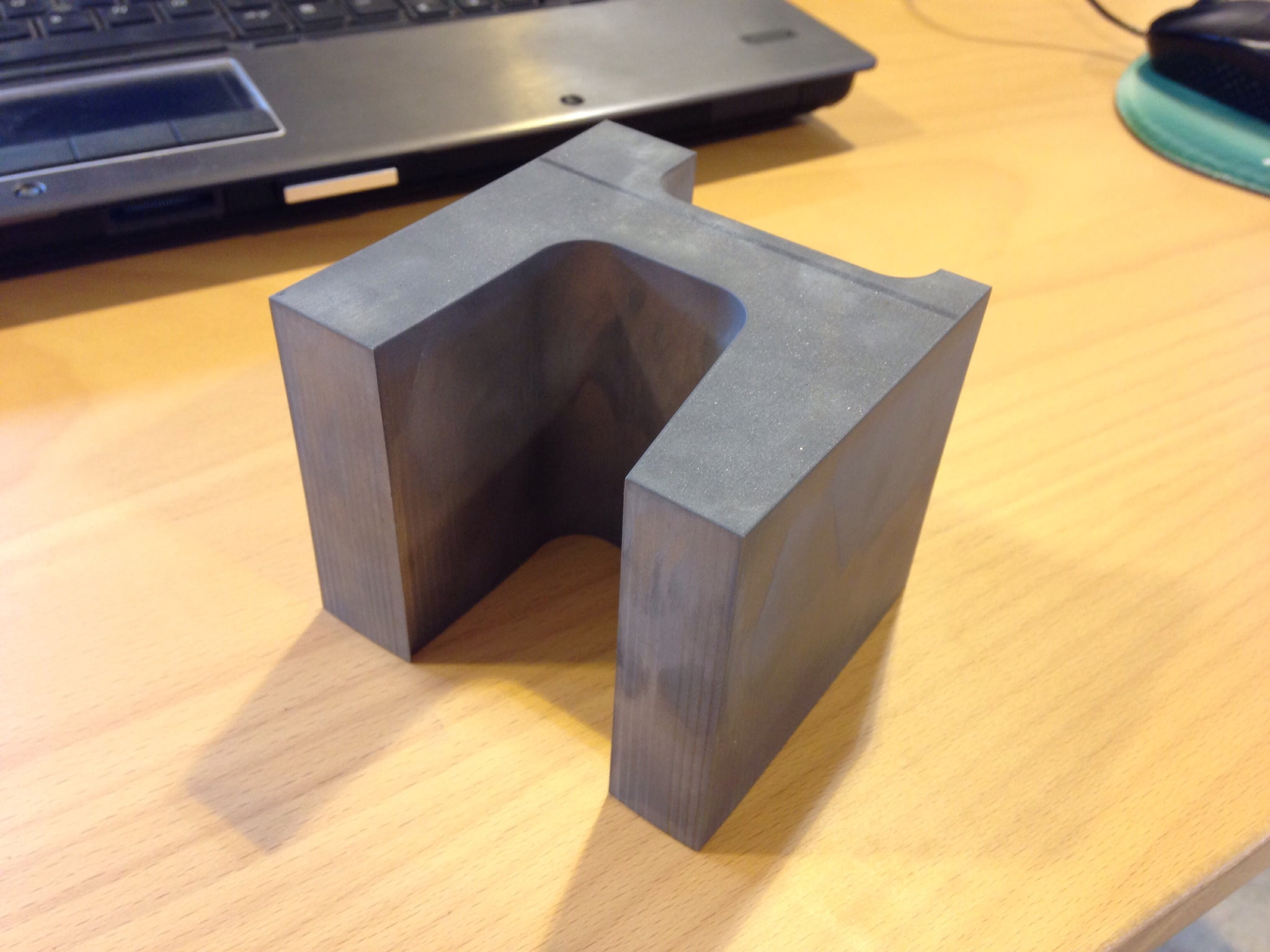

Waterjet cutting is an efficient and precise method for cutting non-ferrous metals, including copper, titanium and brass. The cold abrasive technique preserves the original properties of the materials and is particularly well-suited for cutting metals that are sensitive to heat or for which there are specific requirements for surface quality.

The cold, brittle cutting method is ideal

Benefits of using waterjet cutting for non-ferrous metals:

- Preserved material structure: The cold cutting process prevents thermal impact, ensuring that the metallurgical properties of the metal remain unchanged.

- No heat-affected zone: Unlike thermal cutting methods, waterjet cutting eliminates the risk of heat-related deformations or changes in the material.

- Environmentally friendly process: Waterjet cutting does not generate smoke or harmful vapours, making for a cleaner working environment and reduced environmental impact.

- Versatility: The method can be used to cut through a wide variety of alloys and metals, which makes it flexible for different applications.

Areas of application:

- Mechanical and civil engineering: Manufacturing of precision components and assembled parts where meticulous accuracy is required.

- Precision engineering: Production of detailed parts for watches, jewellery and appliance components where intricate processing is essential.

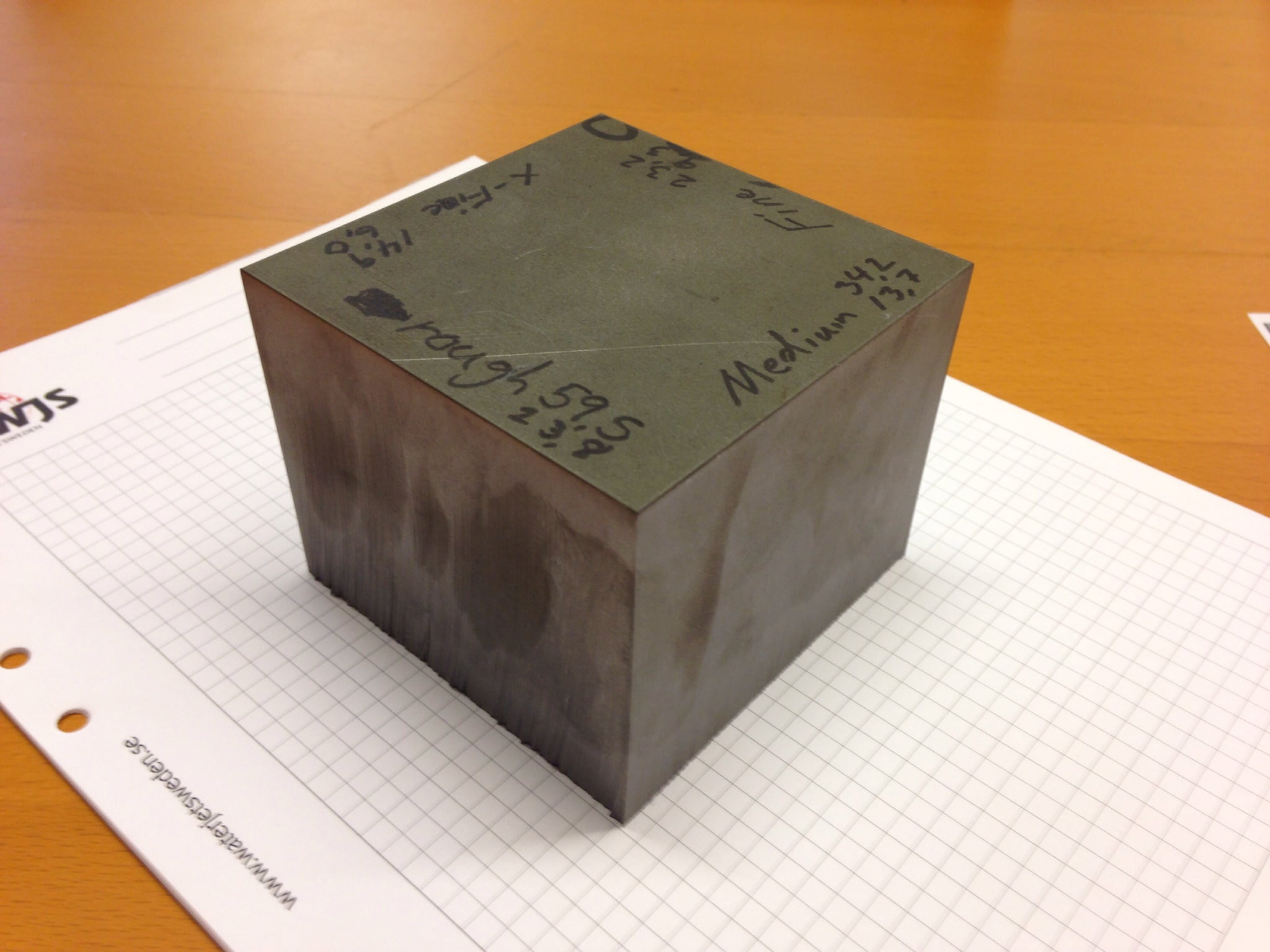

- Materials research: Manufacturing material samples without the occurrence of structural changes, which is important when analysing alloys that are new or difficult to process.

Choosing waterjet cutting for non-ferrous metals ensures a high level of precision and quality, while preserving the integrity of the material

Question: How suitable is waterjet cutting for non-ferrous metals like copper and titanium?

Answer: Waterjet cutting is ideal for sensitive non-ferrous metals such as copper and titanium. The method creates precise kerfs without heat, which preserves the properties of the material. Copper is soft and conducts heat well – waterjet cutting avoids thermal impact and tool wear-and-tear. Titanium, which is otherwise easily deformed by heat, is efficiently cut without any risk of loss of the properties of the metal.

Question: What are the benefits of waterjet cutting compared to thermal cutting methods for non-ferrous metals?

Answer: Waterjet cutting does not causes any heat impact, thus preventing cracks, deformation and metallurgical changes. It does not emit toxic vapours, and the same tools can be used for all alloys, which simplifies the process and increases flexibility when changing materials.

Question: Can waterjet cutting handle high-resistance alloys with a high level of precision?

Answer: Yes, waterjet cutting can handle high-resistance alloys while maintaining precision. As the method does not generate heat, it does not affect the structure of the material, which is crucial when processing advanced materials in the aerospace or energy industries, for example.

Question: How does waterjet cutting affect the surface quality and the need for further finishing work?

Answer: Waterjet cutting produces smooth, clean kerfs with no thermal zones. In standard applications, often only minimal finishing work is required. For finely machined parts, some surfaces may need to be adjusted to remove traces of the abrasive substance used.

Question: Which industries use waterjet cutting for non-ferrous metals?

Answer: Waterjet cutting is used in the automotive, aerospace, electronics, energy, construction, art and engineering industries. It is suitable for precision components made of copper, titanium, aluminium and other light metals where thermal impact must be avoided.